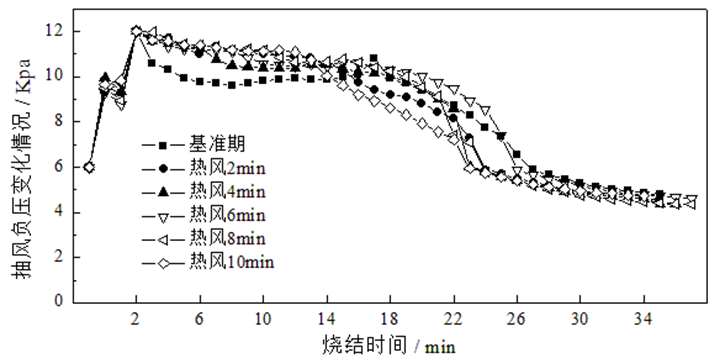

点火时间为2分钟,移开点火器后,基准期3min时烧结负压为10.6Kpa,而废气循环烧结五组平均负压为11.69 Kpa后,废气循环烧结负压均明显上升,增加约1Kpa。现场检测热风罩与烧结杯口接缝处为正压状态,以此认为没有兑入冷风。3~15min废气循环烧结期间,负压平均为10.98Kpa,较基准期负压9.93 Kpa提高了1.05 Kpa。16min时,烧风烧结负压平均为10.08 Kpa,与基准期的10.1 Kpa基本持平。而自17min开始废气循环烧结负压较基准期明显下降,在17-38min期间废气循环烧结平均负压较基准期降低了0.57 Kpa。废气循环烧结期间负压的升高应认为初始烧结的燃烧带增厚所致。

The ignition time was 2 minutes. After the igniter was removed, the negative pressure of sintering was 10.6kpa at the base period of 3min. However, the negative pressure of sintering in the exhaust gas cycle increased significantly after the average negative pressure of sintering in the exhaust gas cycle was 11.69kpa, increasing by about 1Kpa. The joint between hot air cover and sintering cup mouth is under positive pressure, so it is considered that there is no cold air. During the 3-15min waste gas cycle sintering period, the average negative pressure is 10.98kpa, which is 1.05kpa higher than 9.93kpa in the reference period. At 16min, the average negative pressure of air sintering was 10.08kpa, which was basically the same as 10.1 Kpa in the base period. Since 17min, the negative pressure of waste gas cycle sintering decreases obviously compared with the reference period, and the average negative pressure of waste gas cycle sintering during 17-38min decreases by 0.57kpa compared with the reference period. The increase of negative pressure during the waste gas circulation sintering should be attributed to the thickening of the combustion zone in the initial sintering.