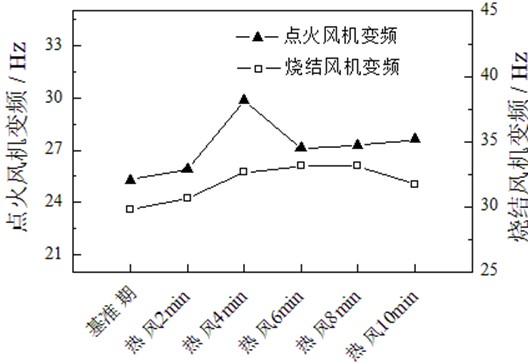

此次烧结杯实验的点火时间全部为2min,点火前,先调整风机变频,控制总管负压在6KPa;点火结束时,再将负压调至12Kpa,并保持固定的频率。废气循环烧结时风机初始运行频率较基准期偏高,分析是初始混合料烧结状况所影响。在废气循环烧结期较基准期偏高1Hz,分析应该是热风温度提高后,初始的燃烧带增厚,影响了烧结热态透气性。

The ignition time of this sintering cup experiment was 2min. Before ignition, the fan frequency conversion was adjusted to control the negative pressure of main pipe at 6KPa. When the ignition is over, the negative pressure is adjusted to 12Kpa and the frequency is kept fixed. The initial operating frequency of the fan during the waste gas circulation sintering is higher than that in the reference period, which is affected by the sintering status of the initial mixture. The sintering stage of exhaust gas cycle is 1Hz higher than that of the reference stage. The analysis should be that the initial combustion zone thickens after the hot air temperature increases, which affects the hot air permeability of sintering.