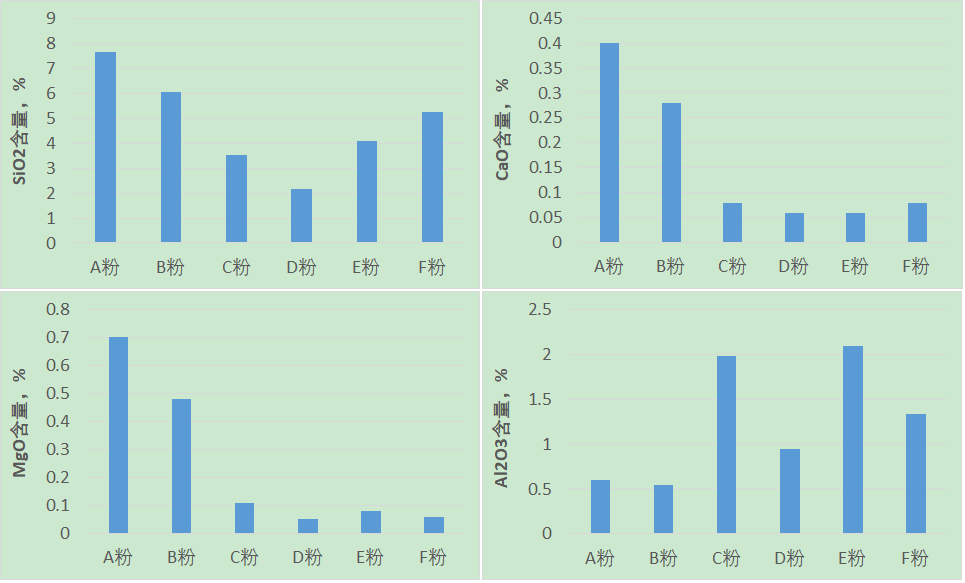

烧结实验的原、燃料使用360m2烧结机流程物料,实验用料全部一次准备好,提前进行混匀。原、燃料理化成份以质检中心检测结果为依据。其中铁矿石原料共6种,分别为A粉、B粉、C粉、D粉、E粉和F粉,对每种铁矿粉的化学成分进行检测,SiO2含量以A粉含量最高,达到7.67%,D粉含量最低,为2.16%;Al2O3含量以C粉含量最高,接近2%,B粉含量最低,为0.54%。

The raw material and fuel of sintering experiment are 360m2 sintering machine process materials. All materials used in the experiment are prepared at one time and mixed in advance. The physical and chemical composition of raw and fuel shall be based on the test results of the quality inspection center. There were 6 kinds of iron ore raw materials, namely A powder, B powder, C powder, D powder, E powder and F powder. The chemical composition of each iron ore powder was detected. The content of SiO2 in A powder was the highest, reaching 7.67%, and that in D powder was the lowest, reaching 2.16%. The content of Al2O3 in POWDER C is the highest, close to 2%, and that in powder B is the lowest, 0.54%.