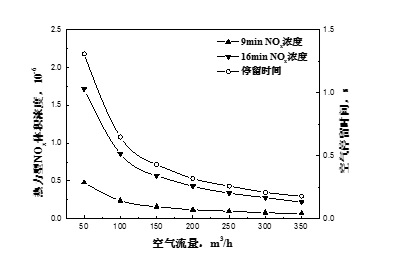

烧结过程热力型NOx生成浓度很低,并随空气流量升高而降低。烧结杯实验中,受料层透气性影响,空气流量变化较大,从而影响空气在料层的停留时间,热力型NOx浓度随空气停留时间的缩短而降低。因此烧结过程中热力型NOx不是主要的生成途径。以空气流量200m3/h计算,NOx体积浓度约为(0.12~0.43)×10-6,烧结时间21.5min,由此可得热力型NOx中N元素的量约为0.002~0.007g。

The concentration of thermal NOx generated in the sintering process is very low, and it decreases with the increase of air flow. In the sintering cup experiment, affected by the air permeability of the material layer, the air flow rate changes greatly, which affects the residence time of the air in the material layer. The thermal NOx concentration decreases with the shortening of the air residence time. Therefore, thermal NOx is not the main way of generation during the sintering process. Calculated with an air flow of 200m3/h, the volume concentration of NOx is about (0.12~0.43)×10-6, and the sintering time is 21.5min. From this, the amount of N element in the thermal NOx is about 0.002~0.007g.