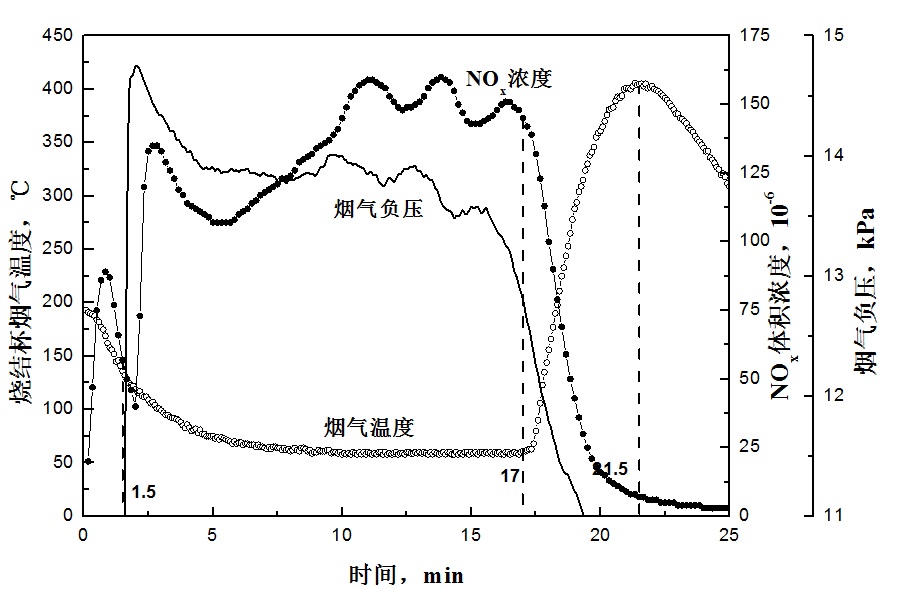

烧结杯实验过程中,在0~1.5min的点火过程中,表层烧结料点燃,随着表层烧结料中N的释放,但由于点火负压较低6000Pa,下部料层尚未燃烧,因此,NOx浓度迅速下降。1.5~17min是烧结过程。点火结束后,增大负压至14000Pa,燃烧层开始向下移动,下部料层开始燃烧,因此NOx体积浓度又迅速升高至135×10-6。17~21.5min是燃烧层到达底部。此时烟气温度迅速升高,而NOx浓度和烟气负压迅速下降。在21.5min时到达烧结终点,烟气温度达到峰值约405℃,随后逐渐降低,NOx浓度基本为零。

During the sintering cup experiment, the surface sintered material ignites during the ignition process of 0~1.5min. With the release of N in the surface sintered material, the ignition negative pressure is lower than 6000Pa, and the lower material layer has not burned, so the NOx concentration Decline rapidly. 1.5~17min is the sintering process. After ignition, increase the negative pressure to 14000Pa, the combustion layer begins to move downwards, and the lower material layer begins to burn, so the NOx volume concentration quickly rises to 135×10-6. 17~21.5min is when the combustion layer reaches the bottom. At this time, the flue gas temperature rises rapidly, while the NOx concentration and flue gas negative pressure drop rapidly. The end of sintering was reached at 21.5 minutes, and the flue gas temperature reached a peak value of about 405°C, and then gradually decreased, and the NOx concentration was basically zero.