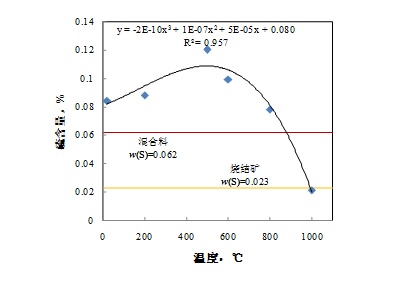

烧结料初始S含量为0.062%,经过SO2吸收实验后,试样中的S含量有较大变化。在850℃以下时,S含量均有不同程度的升高,室温下S的吸收率约为35%,500℃时S的吸收率达到94%。高于850℃时,S含量开始下降,此时烧结混合料开始脱硫。到1000℃时,烧结混合料中的S含量与烧结矿相当。

The initial S content of the sintered material was 0.062%. After the SO2 absorption experiment, the S content in the sample changed greatly. When the temperature is below 850℃, the S content increases to different degrees. The absorption rate of S at room temperature is about 35%, and the absorption rate of S reaches 94% at 500°C. When the temperature is higher than 850°C, the S content begins to decrease, and the sintered mixture begins to desulfurize. At 1000°C, the S content in the sintered mixture is equivalent to that of the sintered ore.