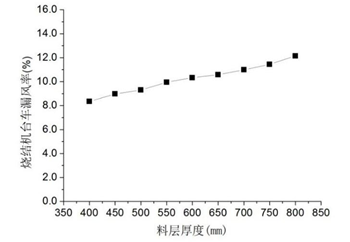

如上图中曲线关系可得,当料层高度400mm时,漏风率为8.355%。当料层高度增加到800mm时,漏风率增大到12.139%。随着料层高度的增加,烧结机台车漏风率增加。但变化量逐渐减小。在实际工业生产中,料层厚度能显著影响烧结生产率、质量以及固体燃料消耗。在多重作用下,生产利用率随料层高度改变会有极值特性,烧结机料层厚度在500-700mm范围内烧结机利用率为最高,且过低或者过高的料层厚度都不利于铁酸钙和Fe2O3矿物相的生产,不利于Fe3O4的存在,将会导致固体燃耗下降。故在烧结领域,现有的烧结机台车料层高度的生产变化范围为500mm~700mm,在此范围内,料层厚度为500mm时,漏风率最低。

As shown in the curve relationship in the above figure, when the height of the material layer is 400mm, the air leakage rate is 8.355%. When the material layer height increases to 800mm, the air leakage rate increases to 12.139%. As the height of the material layer increases, the air leakage rate of the sintering machine trolley increases. But the amount of change gradually decreases. In actual industrial production, the thickness of the material layer can significantly affect the sintering productivity, quality and solid fuel consumption. Under multiple effects, the production utilization rate will have extreme characteristics as the material layer height changes. The sintering machine material layer thickness is in the range of 500-700mm. The sintering machine utilization rate is the highest, and too low or too high material layer thickness is not conducive to The production of calcium ferrite and Fe2O3 mineral phase is not conducive to the existence of Fe3O4 and will lead to a decrease in solid fuel consumption. Therefore, in the field of sintering, the production variation range of the material layer height of the existing sintering machine trolley is 500mm-700mm. Within this range, when the material layer thickness is 500mm, the air leakage rate is the lowest.