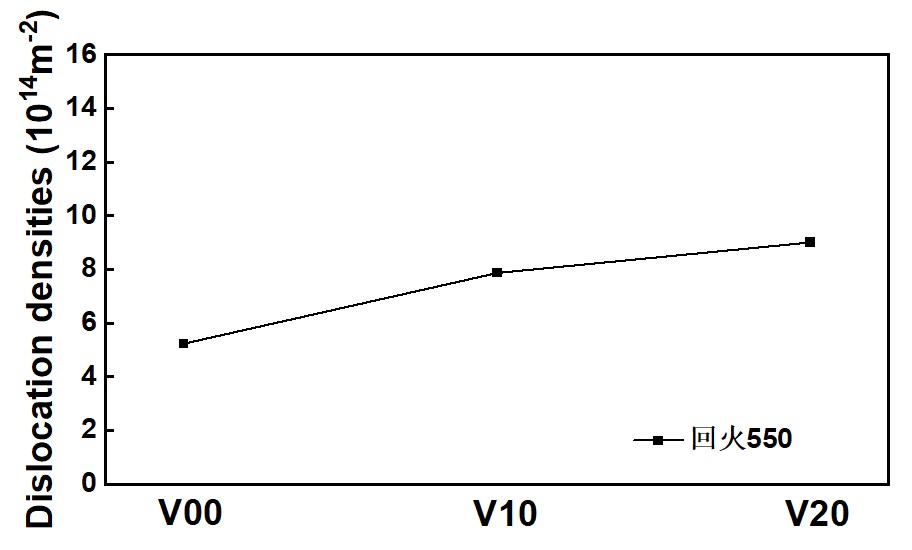

位错密度是通过使用 SmartLab X 射线衍射仪 (XRD) 测量的,靶材为铜靶,扫描角度40°到120°的扫描范围,步长为 0.01°。 通过使用来自样品的 {110}、{200}、{211}、{220} 和 {310} 衍射峰的轮廓,根据改进的Williamson–Hall (MWH) 方法估计位错密度,完全退火纯铁粉用于完全消除仪器宽化。随着V含量的增加,纳米级VC析出相的钉扎作用增强,位错回复速度变缓,导致位错密度增加。

Dislocation density was measured by using a SmartLab X-ray diffractometer (XRD) with a Cu target covering a scan range from 40° to 120° with a step of 0.01°. Dislocation densities were estimated according to a modified Williamson–Hall (MWH) method by using the profiles of {110}, {200}, {211}, {220}, and {310} diffraction peaks from specimens. The fully annealing pure iron powder was used to completely remove instrumental broadening. With the increase of V content, the pinning effect of the nano-scale VC precipitates was enhanced, and the dislocation recovery speed slowed down, resulting in an increase in the dislocation density.