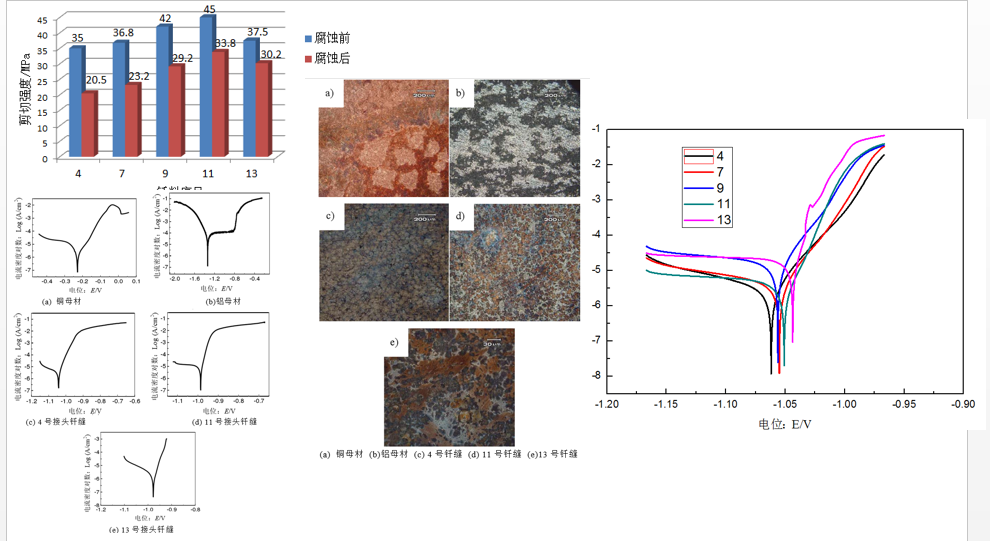

五种钎料接头浸泡腐蚀30天后的剪切强度与腐蚀前剪切强度的对比图。浸泡腐蚀后,五种钎料火焰钎焊的Cu/Al接头腐蚀前剪切强度依次为35MPa、36.8MPa、42MPa、45MPa、37.5MPa;腐蚀30天后,五种Cu/Al接头的剪切强度分别为20.5MPa、23.2MPa、29.2MPa、33.8MPa、30.2MPa,失强率分别为41.4%、36.9%、30.4%、24.8%、19.5%,表明13号钎料接头在3.5wt.%NaCl的盐溶液液中抗腐蚀性能最佳。

The shear strength of five kinds of solder joints after immersion corrosion for 30 days is compared with that before corrosion. After immersion corrosion, the shear strength of Cu / Al joint brazed by five kinds of brazing filler metals before corrosion is 35MPa, 36.8mpa, 42MPa, 45MPa and 37.5mpa respectively; After 30 days of corrosion, the shear strength of five kinds of Cu / Al joints are 20.5mpa, 23.2MPa, 29.2mpa, 33.8mpa and 30.2mpa respectively, and the strength loss rates are 41.4%, 36.9%, 30.4%, 24.8% and 19.5% respectively, indicating that the corrosion resistance of No.13 solder joint is the best in 3.5wt.% NaCl salt solution.