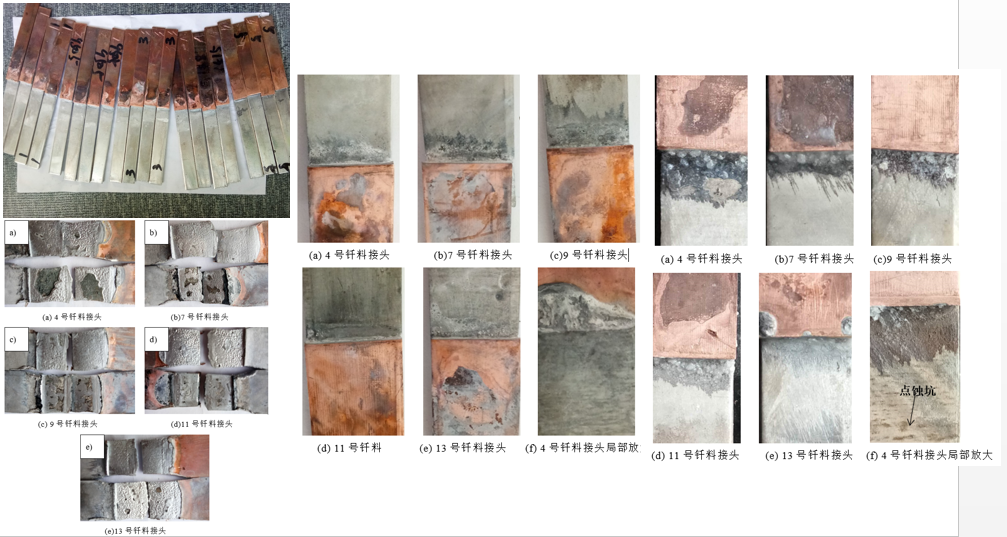

腐蚀前后Cu/Al接头拉伸剪切后试样断口形貌。4号钎焊接头腐蚀30天后和腐蚀前的拉伸剪切试样对比,可以看出,腐蚀前拉伸试样是从钎缝金属靠近铜侧处脱落,腐蚀后拉伸试样是从钎缝金属靠近铝侧处脱落,且脱落部位钎缝金属被腐蚀成大片黑斑。原因主要是4号铝板侧界面主要是由粗大的铝基固溶体组织构成,经过长时间腐蚀后,钎缝表面变得凹凸不平,分布着很多腐蚀微孔,腐蚀液通过蚀孔进入钎料层内部,并沿着那些粗大组织发生晶间腐蚀,使接头铝板侧界面力学性能下降。

The fracture morphology of Cu / Al joint before and after corrosion was analyzed. Comparing the tensile shear specimens of No.4 brazed joint after 30 days of corrosion with those before corrosion, it can be seen that the tensile specimens fall off from the brazing seam metal near the copper side before corrosion, and the tensile specimens fall off from the brazing seam metal near the aluminum side after corrosion, and the brazing seam metal is corroded into large black spots. The main reason is that the side interface of No.4 aluminum plate is mainly composed of coarse aluminum based solid solution structure. After a long time of corrosion, the surface of solder joint becomes uneven, with many corrosion micropores distributed. The corrosion liquid enters into the solder layer through the corrosion pores, and intergranular corrosion occurs along those coarse structures, which reduces the mechanical properties of the side interface of aluminum plate.