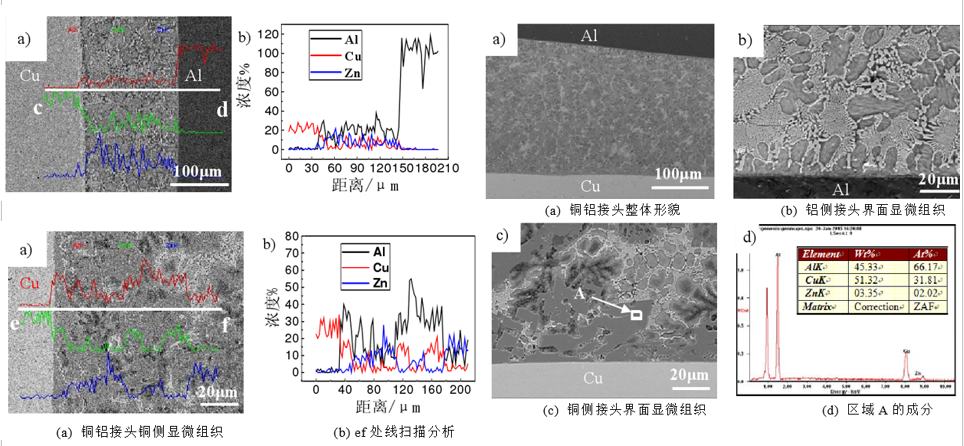

Cu元素浓度在铜母材向钎缝方向上逐渐降低,在铜侧界面处Cu原子的浓度较高,因此在焊后冷却过程中,铜侧界面处的Cu原子就容易与钎料中的Al、Zn原子结合生成锌铝铜三元金属间化合物,又由于Al元素浓度在铝母材向钎缝方向上也逐渐降低,加之钎料合金中添加的Cu和基体中Al结合形成少量的CuAl2相,铜侧Al含量进一步减少,界面层厚度变薄。

The Cu concentration decreases gradually from the copper base metal to the brazing seam, and the Cu concentration is higher at the copper side interface. Therefore, during the cooling process after welding, the Cu atoms at the copper side interface are easy to combine with Al and Zn atoms in the solder to form Zn Al Cu ternary intermetallic compound, and the Al concentration also decreases gradually from the aluminum base metal to the brazing seam, In addition, a small amount of CuAl2 phase is formed by the combination of Cu added in the solder alloy and Al in the matrix, the Al content on the copper side is further reduced, and the thickness of the interface layer becomes thinner.