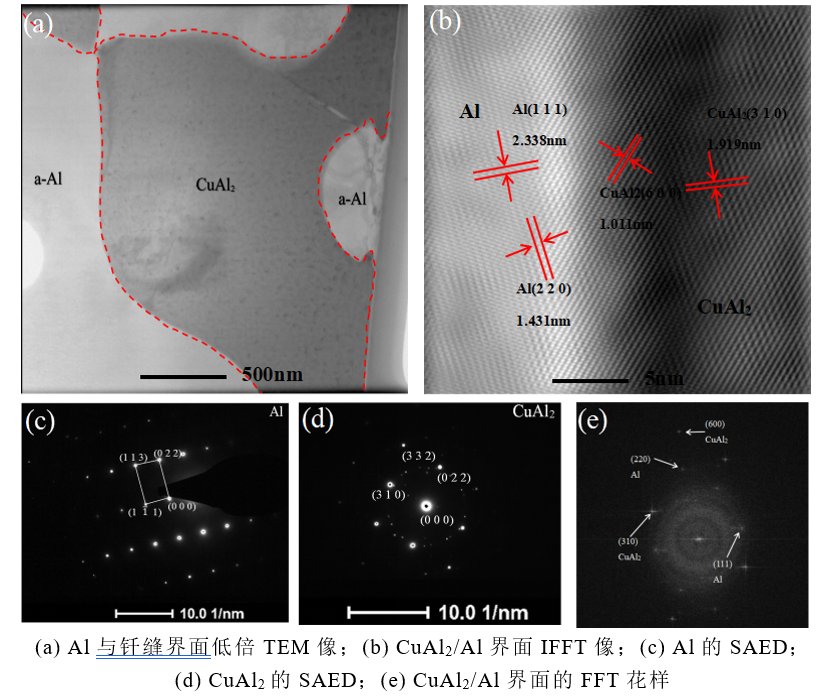

图2.58(a)为低倍TEM像,图2.58(b)-(e)为图2.58(a)中不同微区的电子衍射花样。图2.58 (d)为CuAl2晶粒的SAED图样,其电子衍射图样由多个衍射环组成,表明CuAl2具有不同的晶体取向,在钎缝中随机分布。如图所示,图2.58 (b)为CuAl2与Al界面的IFFT像,其中图左侧为Al晶面,图右侧为CuAl2,通过标定对应的CuAl2与Al界面HRTEM的FFT斑点,分别标出了Al的(220)和(111)晶面,以及CuAl2的(310)和(660)晶面。并通过查找pdf卡片,得到CuAl2与Al的晶面间距分别为dCuAl2(111)(220)=2.338nm、1.431nm;dAl(310)(600)=1.919nm、1.011nm,计算得CuAl2(310)/Al(111)晶格失配率为0.179,CuAl2(600)/Al(111)的晶格失配率为0.567,而CuAl2(310)/Al(220)晶格失配率为0.341,CuAl2(600)/Al(220)的晶格失配率为0.293。通过计算得到的结果。CuAl2和Al的界面基本属于良好的半共格界面结构,相较于Cu9Al4与CuAl2界面,此界面具有比较好的晶格匹配。

Fig. 2.58 (a) shows TEM images at low power, and Fig. 2.58 (b) - (e) shows electron diffraction patterns in different micro-regions in Fig. 2.58 (a).Fig. 2.58 (d) shows the SAED pattern of CuAl2 grains, whose electron diffraction pattern consists of multiple diffraction rings, indicating that CuAl2 has different crystal orientations and randomly distributed in the crack.As shown in Fig. 2.58 (b), IFFT images of CuAl2 and Al interfaces are shown, in which Al crystal faces are shown on the left side of the figure and CuAl2 on the right side of the figure. The (220) and (111) crystal faces of Al are marked by demarcating the corresponding FFT spots of CuAl2 and Al interfaces.And (310) and (660) crystal faces of CuAl2.By searching PDF card, the crystal plane spacing of CuAl2 and Al is DCuAl2 (111) (220) =2.338nm and 1.431nm, respectively.DAl (310)(600)=1.919nm and 1.011nm, the lattice mismatch ratio of CuAl2(310)/Al(111) was calculated to be 0.179, and the lattice mismatch ratio of CuAl2(600)/Al(111) was 0.567.The lattice mismatch ratio of CuAl2(310)/Al(220) is 0.341, and that of CuAl2(600)/Al(220) is 0.293.The result of the calculation.The interface of CuAl2 and Al basically belongs to a good semi-coherent interface structure. Compared with the interface of Cu9Al4 and CuAl2, this interface has better lattice matching.