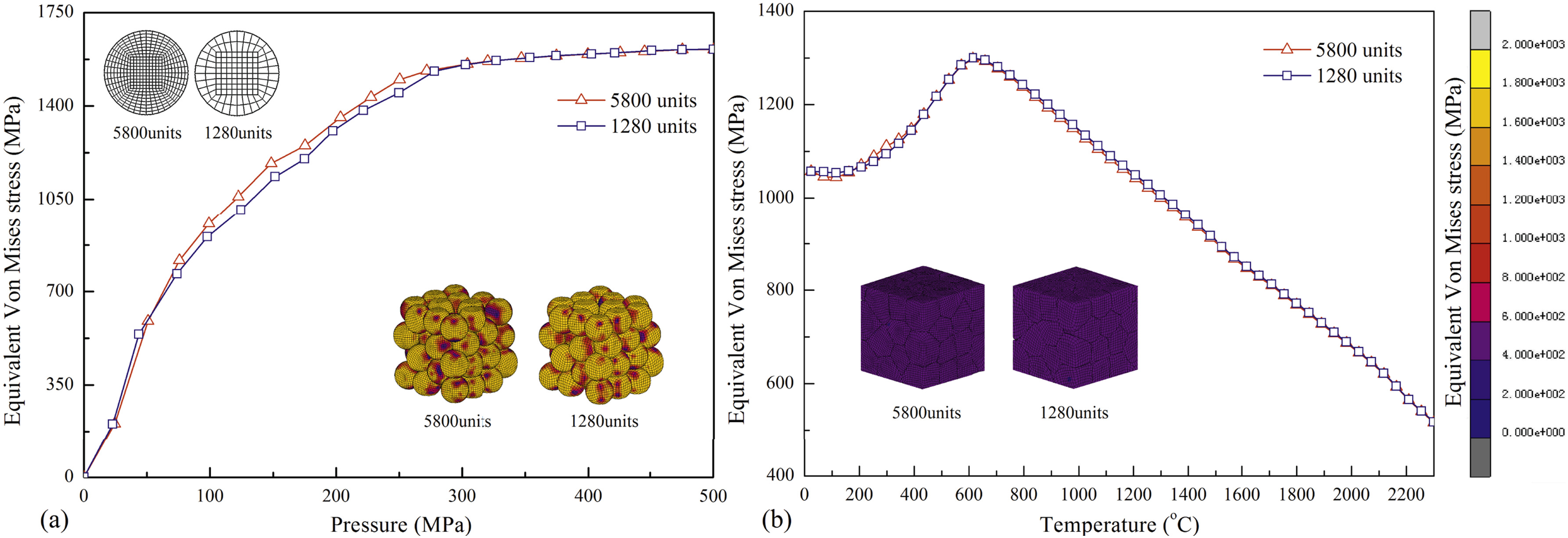

通过有限元软件MSC.Marc从颗粒尺度对不同尺寸的钨粉颗粒的单向模压和固相烧结过程进行了模拟。分析了颗粒尺寸(1μm, 5μm, 10μm, 15μm, 20μm, 50μm, 100μm)及工艺参数(压制压力、烧结温度)对压制过程和烧结过程的影响,并从宏观尺度(相对密度)和微观尺度(应力、应变、颗粒变形)对钨粉末压坯和烧结坯的性能进行了表征及对比分析。得出了制备具有高致密度纯钨制件的最优工艺参数和颗粒尺寸,颗粒的变形机理及粉末冶金过程的致密化机理。

The finite element software MSC.Marc simulates the unidirectional molding and solid-phase sintering process of tungsten powder particles of different sizes from the particle scale. The effects of particle size (1μm, 5μm, 10μm, 15μm, 20μm, 50μm, 100μm) and process parameters (pressing pressure, sintering temperature) on the pressing process and sintering process are analyzed, and the macro-scale (relative density) and micro-scale ( Stress, strain, particle deformation) were used to characterize and compare the properties of tungsten powder compacts and sintered compacts. The optimal process parameters and particle size for the preparation of high-density pure tungsten parts, the deformation mechanism of the particles and the densification mechanism of the powder metallurgy process are obtained.