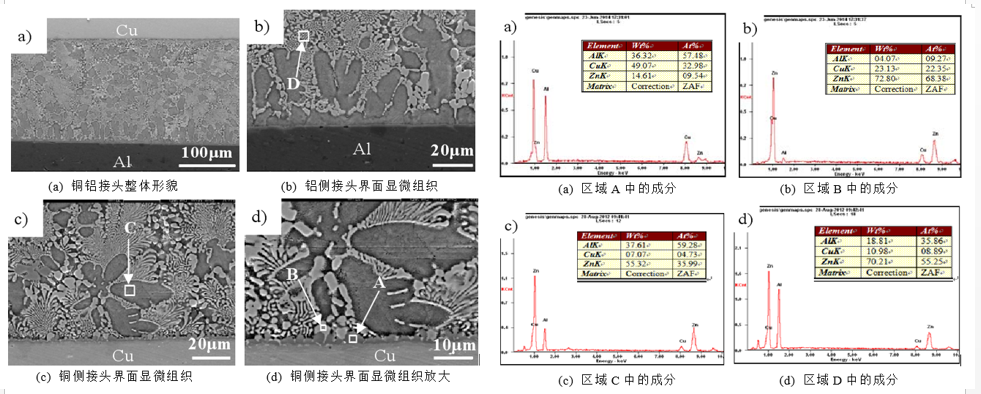

从火焰钎焊Cu/Al接头的显微组织可以看出,钎缝中主要以Zn基固溶体和Al基固溶体为主,钎缝中没有针状化合物出现。结合相图和能谱分析结果可知,钎缝中白色相为Zn基固溶体,粗大的黑色块状相为Al基固溶体,黑白相间的为Zn-Al共晶组织。高温下锌铝之间互溶度很大,钎焊过程中铝母材中的Al原子与钎料中Zn原子相互扩散速度很快,使Al母材一侧界面附近的Al含量很高,因此,在铝母材一侧界面附近形成了单体面积大且分布密集的α(Al)固溶体。

The microstructure of cu/al joint by flame brazing shows that Zn based solid solution and Al based solid solution are the main parts in the brazing joint, and no needle compound appears in the brazing joint. According to the phase diagram and the energy spectrum analysis, the white phase in the solder joint is Zn based solid solution, the coarse black block phase is Al based solid solution, and the black and white phase is Zn Al eutectic structure. The mutual solubility of zinc and aluminum is very high at high temperature. During brazing, the Al atoms in the base metal and Zn atoms in the brazing process spread rapidly, which makes the Al content near the interface of one side of the Al base metal very high. Therefore, the monomer area is large and the distribution is dense near the interface of one side of the aluminum base metal α( Al) solid solution.