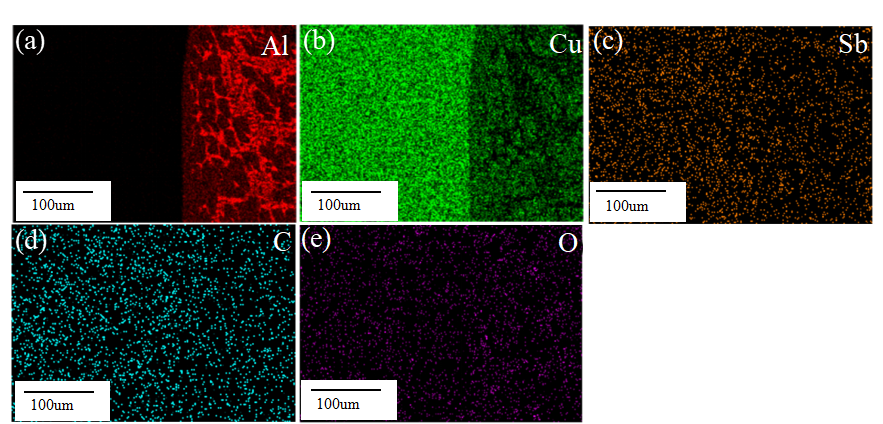

通过微观组织照片及EDX可以发现BAl88Si钎料与Cu基体进行了充分的反应。母材中的Cu元素扩散程度明显高于钎料中的Al元素,并在界面侧出现了明显的分层现象。而Al元素在钎缝中主要以枝晶状分布,其余部分Al元素在界面侧与Cu元素共晶存在。

Through the microstructure photos and EDX, it can be found that the BAl88Si brazing filler metal reacts sufficiently with the Cu matrix. The diffusion degree of Cu element in the base metal is obviously higher than that of Al element in the brazing filler metal, and obvious delamination phenomenon appears on the interface side. The Al element is mainly distributed in the form of dendrites in the brazing joint, and the remaining part of Al element is eutectic with Cu element on the interface side.