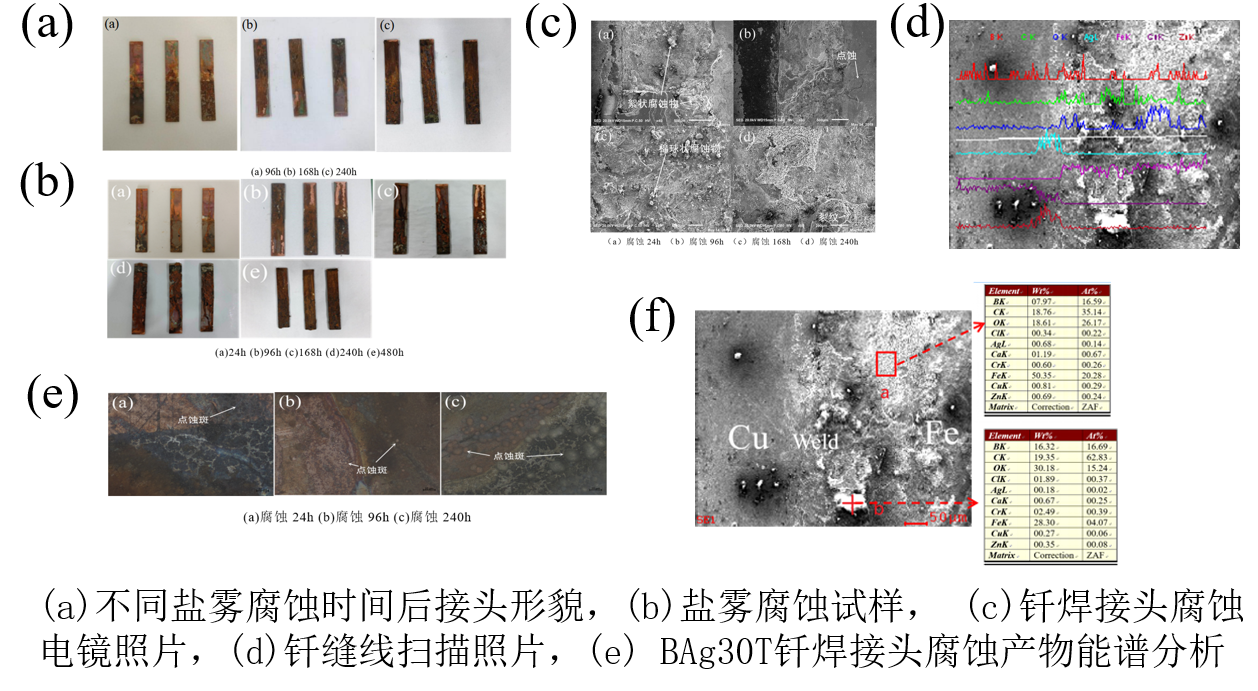

通过微观表面观察盐雾腐蚀过程中既有点蚀的发生,也有全面腐蚀的发生,腐蚀时间越长的全面腐蚀现象更为严重,且腐蚀产物覆盖面积显著增加。从腐蚀过程中看出钢侧的腐蚀较为严重,更易腐蚀。O元素的分布在腐蚀物上,说明O元素参与了腐蚀的过程,Ag元素和Zn元素分布位置较为集中,原因是Ag元素和Zn元素是钎料中的元素,应较为集中分布在焊缝位置,但Ag元素和Zn元素分布位置较宽超过焊缝,是Ag元素和Zn元素从焊缝向母材扩散,母材Fe元素和Cu元素与Ag元素和Zn元素有交叉位置,所以Fe元素和Cu元素由母材向焊缝扩散。

Through the microscopic surface observation of the salt spray corrosion process, both pitting and general corrosion occur. The longer the corrosion time, the more serious the general corrosion phenomenon, and the corrosion product coverage area is significantly increased. It can be seen from the corrosion process that the corrosion on the steel side is more serious and more prone to corrosion. The distribution of O element on the corroded material indicates that O element is involved in the corrosion process. The distribution of Ag and Zn elements are concentrated. The reason is that Ag and Zn are elements in the solder and should be more concentrated in the welding seam. , But the distribution of Ag and Zn elements is wider than that of the weld. It is the diffusion of Ag and Zn from the weld to the base metal. The base metal Fe and Cu have cross positions with Ag and Zn, so Fe and The Cu element diffuses from the base metal to the weld.