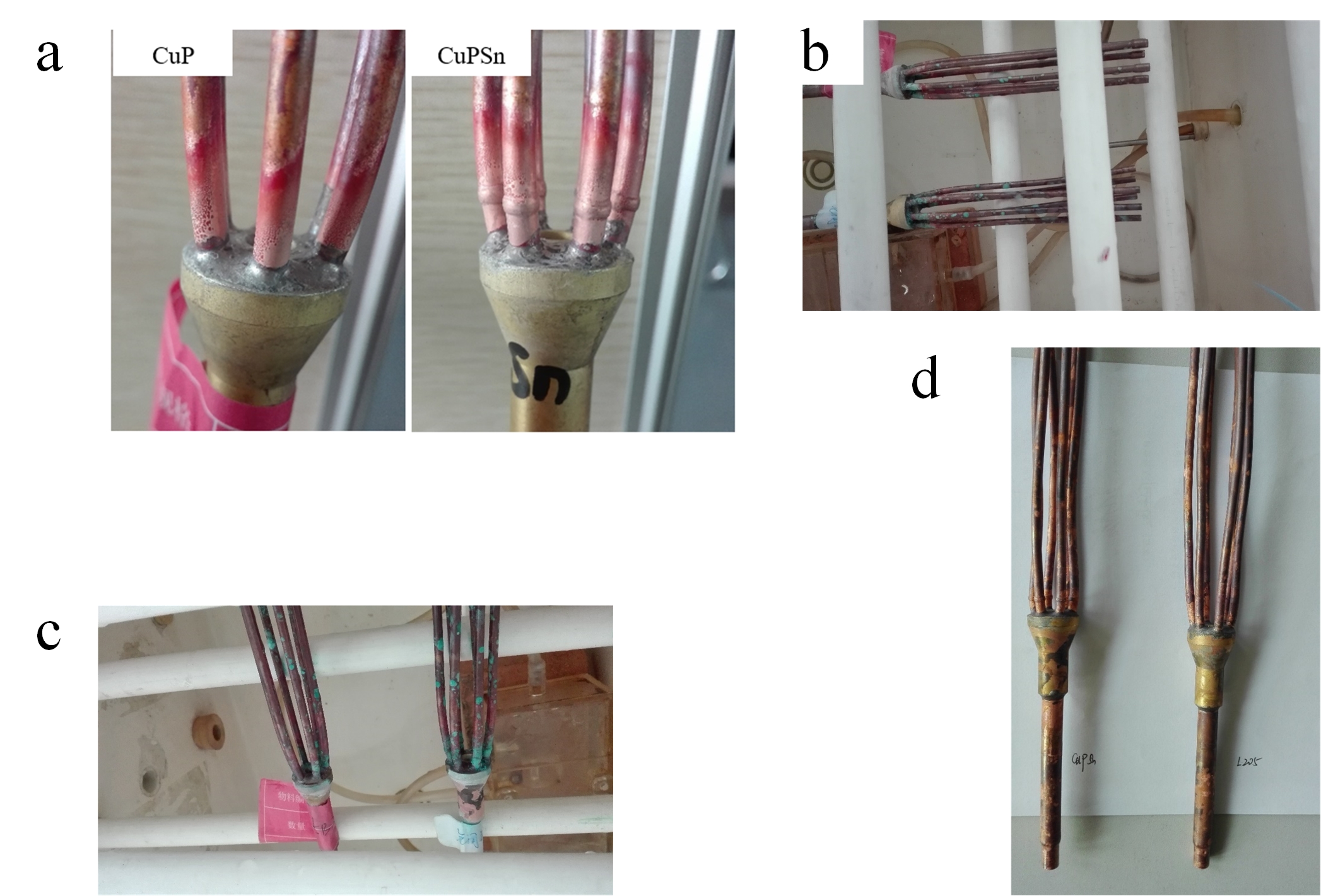

图a、b、c为分别为CuP和CuPSn钎料钎焊接头盐雾腐蚀前、腐蚀24h和腐蚀72h的腐蚀形貌图。没有进行盐雾腐蚀时,焊缝区域光亮,焊缝填充良好。将焊接件进行盐雾腐蚀之后,两种钎料焊接件均出现一定程度的腐蚀。工件表面均残留一定量的蓝绿色的磷酸盐化合物。将腐蚀72h后的工件用超声波清洗后所得形貌如图d所示,工件焊缝区域与图a相比,颜色发黑,两种焊料均发生腐蚀。

Figures a, b, and c are respectively the corrosion morphology of CuP and CuPSn solder joints before salt spray corrosion, corrosion 24h and corrosion 72h. When there is no salt spray corrosion, the weld area is bright and the weld is well filled. After the welding parts were corroded by salt spray, the two kinds of solder welding parts showed a certain degree of corrosion. A certain amount of blue-green phosphate compound remains on the surface of the workpiece. The morphology of the workpiece corroded for 72 hours after ultrasonic cleaning is shown in Figure d. Compared with Figure a, the weld area of the workpiece is darker in color, and both solders are corroded.