将AB和ZrO2/AB树脂用甲苯稀释至20%的浓度。将混合分散体旋涂在硅载玻片或玻璃载玻片上形成薄膜,在100°C下固化30 min,然后在150°C下固化1.5 h,得到固化的ZrO2/AB杂化膜。为了进行比较,我们还将等量的A kit和B kit树脂直接混合制备了纯OE-6636硅树脂,制备薄膜的步骤与ZrO2/AB树脂相同。

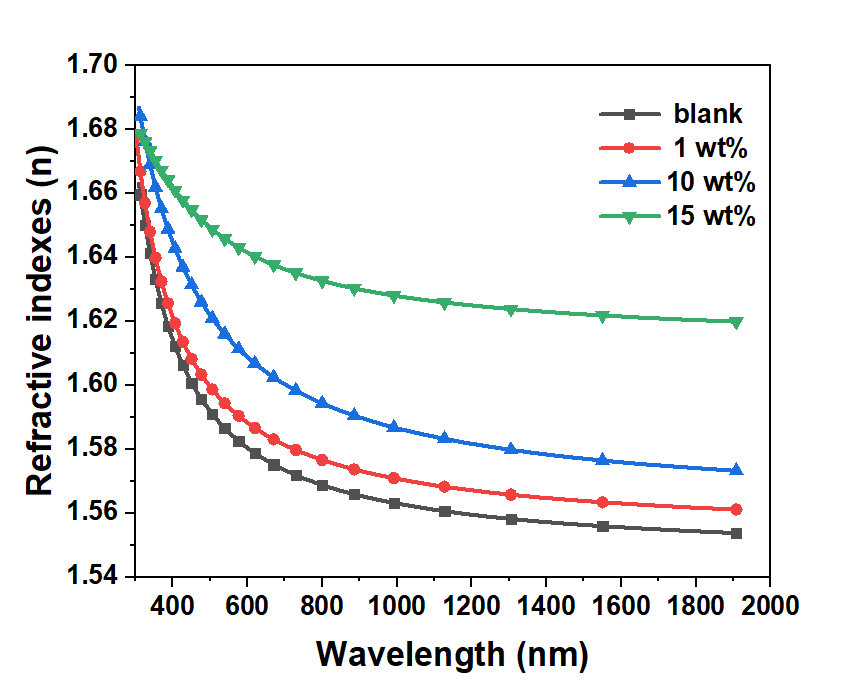

采用椭偏移对不同丙醇锆添加量(0,1,10,15wt%)的AB膜和ZrO2/AB固化膜测其折射率。结果表明,添加丙醇锆的含量可以显著提高封装材料的折射率。

The AB and ZrO2/AB resins were diluted with toluene to a concentration of 20%. The mixed dispersion was rotated onto silicon or glass slides to form a film. Subsequently they cured at 100 °C for 30 min, and then 150 °C for 1.5 h to obtain cured ZrO2/AB hybrid films. For comparison, pure OE-6636 silicone resin was also prepared by directly mixing the A kit and B kit resins with equal amounts and the procedures for preparation of thin films were similar as those of ZrO2/AB resins.

The refractive index of AB films and ZrO2/AB cured films with different zirconium propanol content (0,1,10,15 wt%) was measured by elliptic migration. The results show that the addition of zirconium propanol can significantly improve the refractive index of packaging materials