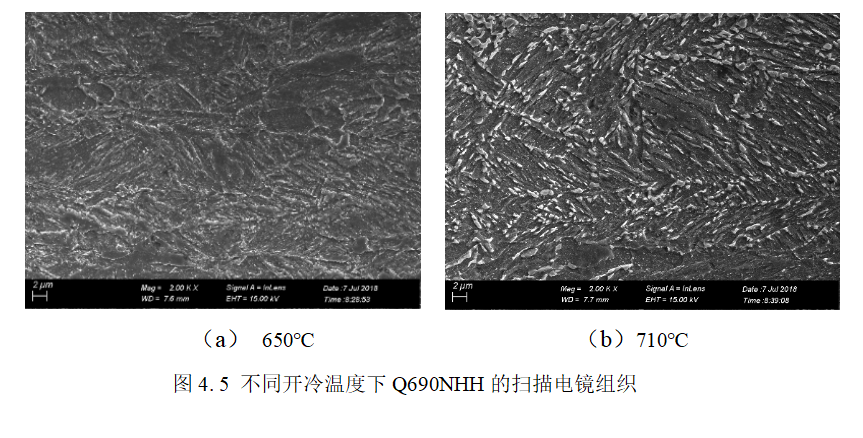

在不同开冷温度下的试验钢扫描电镜照片如图4.5所示,开冷温度为650℃~680℃时,铁素体晶界处存在着少量的小尺寸M-A岛,贝氏体边界不清;开冷温度为710℃~740℃的范围内,组织明显细化,针状铁素体数量急剧减少,多数转变板条贝氏体,M-A数量明显增多,该开冷温度下的组织以板条贝氏体为主,板条边界清晰、组织均匀,M-A岛大多聚集在始奥氏体晶界处且数量明显增多,这种软硬相复合的组织结构可以进一步提高钢板的强度,改善低温冲击韧性。

The SEM photos of the test steel at different opening and cooling temperatures are shown in Figure 4.5. When the opening and cooling temperature is 650℃~680℃, there are a few small-sized MA islands at the ferrite grain boundaries, and the bainite boundary is unclear. ; When the open cooling temperature is 710℃~740℃, the structure is obviously refined, the number of acicular ferrite decreases sharply, most of the lath bainite is transformed, and the amount of MA increases significantly. Strip bainite is the main component, with clear slab boundaries and uniform organization. Most of the MA islands are concentrated at the beginning austenite grain boundaries and the number is significantly increased. This soft and hard phase composite structure can further increase the strength of the steel plate and improve the low temperature Impact toughness.