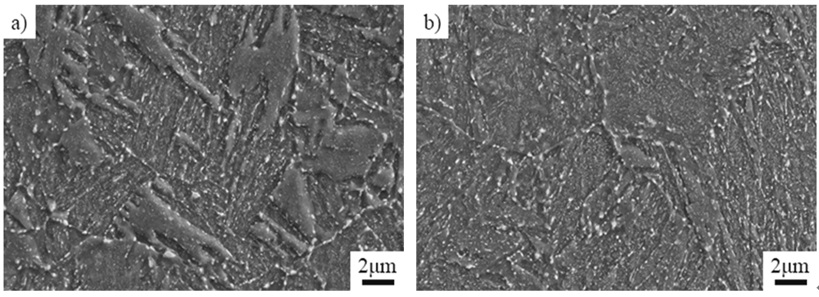

图(a)和(b)分别为DZ2(0.17V0Nb)加热到850℃、900℃保温1h,油淬,然后在675℃回火4h,其显微组织的SEM形貌。由图可知,DZ2(0.17V0Nb)钢组织均为回火马氏体,部分马氏体板条已发生回复,且试验钢在900℃保温1h获得的组织更粗大,但析出相尺寸相对细小,这与0.05V钢组织变化规律相同;同时也发现,在相同淬火温度保温时DZ2(0.18V-0.04Nb)钢获得更细小的组织。

Figure (a) and (b) respectively show the SEM morphology of DZ2 (0.17v0Nb) after heating at 850℃ and 900℃ for 1h, oil quenching, and then tempering at 675℃ for 4h. It can be seen from the figure that the microstructure of DZ2 (0.17V0Nb) steel is tempered martensite, and some martensite slat has recovered, and the microstructure of the test steel is coarser after holding at 900℃ for 1h, but the size of precipitated phase is relatively small, which is the same as that of the 0.05V steel. It was also found that DZ2 (0.18V-0.04Nb) steel obtained finer microstructure at the same quenching temperature.