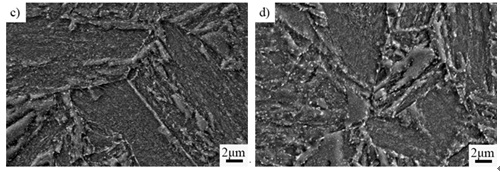

图(c)和(d)分别为DZ2(0.05V0Nb)钢经900℃油淬及在675℃回火时间分别为1h和4h后的SEM组织形貌。由图可以知,DZ2(0.05V0Nb)经过回火后组织均为回火马氏体,且随着回火温度的升高,马氏体板条没有明显的变化。图中可以发现在原始奥氏体晶界、马氏体板条束界和板条块界面上有大量的合金渗碳体的析出,且随着回火温度的升高合金渗碳体的析出量逐渐增多,尺寸逐渐增大。

Figure (c) and (d) show the SEM morphology of DZ2 (0.05V0Nb) steel after oil quenching at 900℃ and tempering at 675℃ for 1h and 4h, respectively. As can be seen from the figure, the microstructure of DZ2 (0.05v0Nb) after tempering is all tempered martensite, and with the increase of tempering temperature, the martensite slat has no obvious change. In the figure, it can be found that there are a lot of alloy cementite precipitation at the original austenite grain boundary, martensitic strip bundle boundary and the interface of the strip block, and with the increase of tempering temperature, the precipitation amount of alloy cementite gradually increases, and the size of the alloy cementite gradually increases.