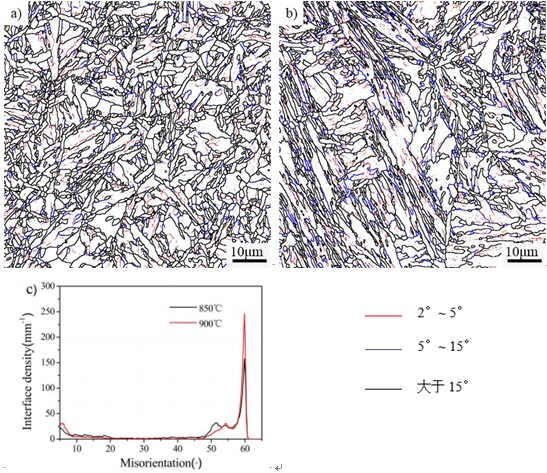

图(a)和(b)分别为DZ2(0.05V0Nb)钢850℃和900℃保温1h后再675℃回火4h的GB图,在850℃保温时,基体中的大角度界面明显较多。图中(c)为在850℃、900℃保温两种热处理工艺下的0.05V钢界面密度—取向差分布图,根据EBSD的扫描步长、区域及标定的点数,计算出的大角度界面密度分别为1788 mm-1和1723mm-1。经过测量,在850℃、900℃淬火后得到的板条块宽度分别为2.2µm和3.0µm。

Figure (a) and (b) are GB diagrams of DZ2 (0.05V0Nb) steel held at 850℃ and 900℃ for 1h and then tempered at 675℃ for 4h, respectively. When held at 850℃, the large Angle interface in the matrix is obviously more. Figure (c) shows the interface densive-orientation difference distribution of 0.05V steel under 850℃ and 900℃ heat treatment processes. According to the scanning step size, area and calibration point of EBSD, the calculated large-angle interface densities are 1788 mm-1 and 1723mm-1, respectively. After quenching at 850℃ and 900℃, the width of the slabs was measured to be 2.2µm and 3.0µm, respectively.