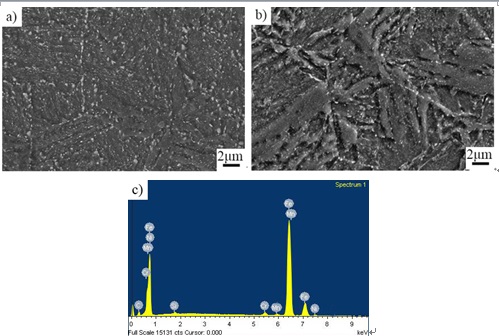

在图中(a)和(b)分别为DZ2(0.05V0Nb)钢850℃和900℃保温1h油淬火至室温后675℃回火4h后的SEM形貌及析出相能谱图,DZ2(0.05V0Nb)钢在850℃保温1h获得的组织更加细小,且第二相的析出量也明显较多,这主要是因为在850℃保温时存在未完全固溶的V,淬火时以碳化物的形式析出。而在图中,(c)图为850℃保温1h回火后基体中析出相的能谱图,由此可知,其析出相主要为合金碳化物,而V的析出相尺寸通常为纳米级,能谱很难检测到。

In the figure (a) and (b), SEM morphology and energy spectrum of precipitated phase of DZ2 (0.05V0Nb) steel after oil quenching at 850℃ and 900℃ for 1h and tempering at 675℃ for 4h, respectively. The microstructure of DZ2 (0.05V0Nb) steel obtained at 850℃ for 1h is finer, and the precipitation amount of the second phase is also significantly larger. This is mainly due to the existence of incomplete solid solution V at 850℃, and precipitation in the form of carbide during quenching. In the figure, (c) is the energy spectrum of the precipitated phase in the matrix after holding at 850℃ for 1h tempering. It can be seen that the precipitated phase is mainly alloy carbide, while the size of the precipitated phase of V is usually nanoscale, so it is difficult to detect the energy spectrum.