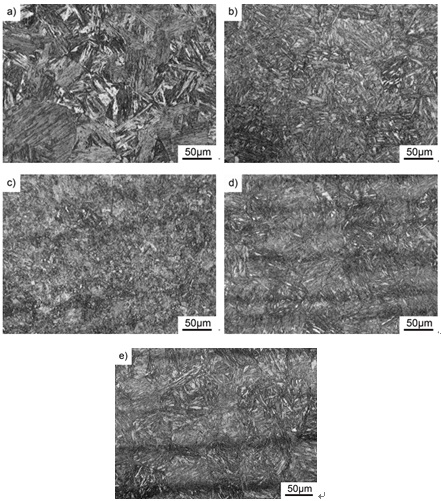

图(a)为DZ2(0.05V0Nb)钢900℃淬火的光学显微镜(OM)下的组织形貌,图(b)(c)(d)(e)为DZ2(0.05V0Nb)钢经900℃淬火后分别在600℃、625℃、650℃、675℃回火1h处理后在光学显微镜(OM)下的组织形貌。由图可知,0.05V钢经淬火后的微观组织为淬火马氏体板条,经不同温度回火后三种钢的微观组织都为回火马氏体板条,且随回火温度的上升,部分马氏体板条发生溶解,回火温度升至675℃时,可以看到马氏体板条明显发生回复。

Figure (a) shows the microstructure morphology of DZ2 (0.05V0Nb) steel under optical microscope (OM) after quenching at 900℃. Figure (b) (c) (d) (e) shows DZ2 (0.05V0Nb) steel after quenching at 600℃, 625℃, 650℃ and 675℃ respectively .Microstructure morphology under optical microscope (OM) after tempering for 1h. It can be seen from the figure that the microstructure of 0.05V steel after quenching is tempered martensite lath, and the microstructure of the three kinds of steel after tempering at different temperatures are tempered martensite lath, and with the rise of tempering temperature, part of martensite lath dissolve, and when the tempering temperature rises to 675℃, it can be seen that the martensite lath obviously recover.