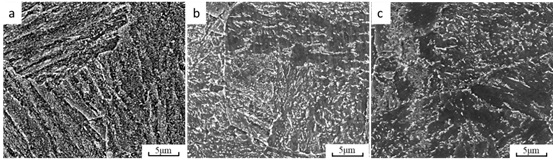

图d、e和f分别为DZ(连铸)钢边部、1/2半径和心部三个位置的SEM组织形貌,由图可知,试验钢经过回火后有大量的合金渗碳体析出,其中马氏体中析出量显著多于贝氏体。贝氏体属于半扩散型相变,相变时有部分碳扩散到奥氏体中,剩余奥氏体在发生马氏体相变时,以切变形式进行,由于相变速度快,碳来不及扩散,均保留在马氏体中,形成过饱和固溶体,在回火时马氏体中碳以合金渗碳体形式析出。

Figure D, E and F respectively show the SEM morphology of the edge, 1/2 radius and center of DZ (continuous casting) steel. It can be seen from the figure that a large amount of alloying cementite precipitates out of the test steel after tempering, among which the precipitate amount in martensite is significantly more than that in bainite. Bainite belongs to half type diffusion phase transformation, phase change are part of the carbon diffusion in the austenite, the residual austenite in the case of martensite phase transformation, in the form of shear, due to phase change fast, enough time carbon diffusion, are retained in the martensite, form the supersaturated solid solution, when tempering martensite in carbon in the form of alloy cementite precipitate.