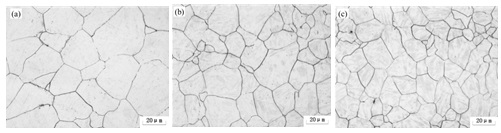

图(a)(b)(c)分别为DZ2(0.05V0Nb)钢在950℃淬火、850℃淬火和850℃两次淬火的奥氏体晶粒形貌,由图可知,奥氏体晶粒均为等轴晶粒,通过直线截距法统计可知,DZ2(0.05V0Nb)钢在950℃淬火、850℃淬火和850℃两次淬火奥氏体平均晶粒尺寸分别为29.2μm、20.5μm、14.9μm,可见随着淬火温度的降低和淬火次数的增加奥氏体晶粒尺寸逐渐减小。

Figure (a), figure (b) and Figure (c) respectively show the austenite grain morphology of DZ2 (0.05V0Nb) steel after quenching at 950℃, 850℃ and 850℃. It can be seen from the figure that austenite grains are equiaxed grains. The average austenite grain size of DZ2 (0.05V0Nb) steel after quenching at 950℃, 850℃ and 850℃ are 29.2μm, 20.5μm and 14.9μm, respectively. It can be seen that the austenite grain size decreases gradually with the decrease of quenching temperature and the increase of quenching times.