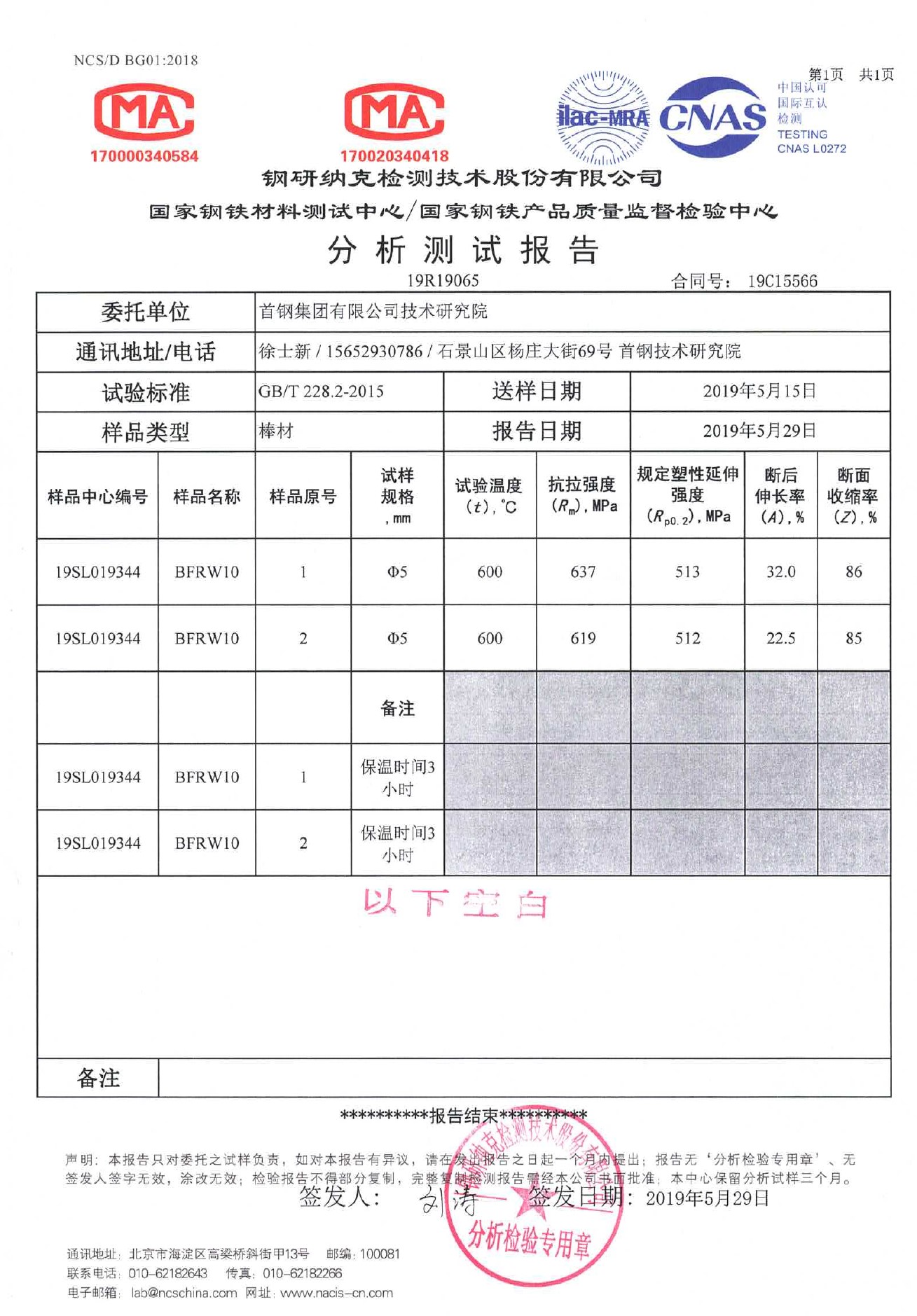

通过用户网带炉淬火+回火热处理工艺,实现强韧性匹配。热处理工艺制度:奥氏体化温度900℃保温1小时,在620-630℃下保温2小时,实现螺栓的室温和高温稳定性能。在600℃下保温3小时的实验的条件下,10.9级耐火耐候螺栓钢的高温拉伸性能,抗拉强度≥600Mpa,断面收缩率≥85%,断后伸长率分别为22.5和32%。

The matching of strength and toughness can be realized through the process of user mesh belt furnace quenching and tempering heat treatment. Heat treatment process: Austenitizing temperature 900℃ for 1 hour, at 620-630℃ for 2 hours, to achieve room temperature and high temperature stability of bolts. The tensile properties of 10.9 grade refractory weather-resistant bolted steel at high temperature, tensile strength ≥600Mpa, area shrinkage ≥85%, elongation after fracture are 22.5 and 32%, respectively, under the experimental conditions of holding for 3 hours at 600℃.