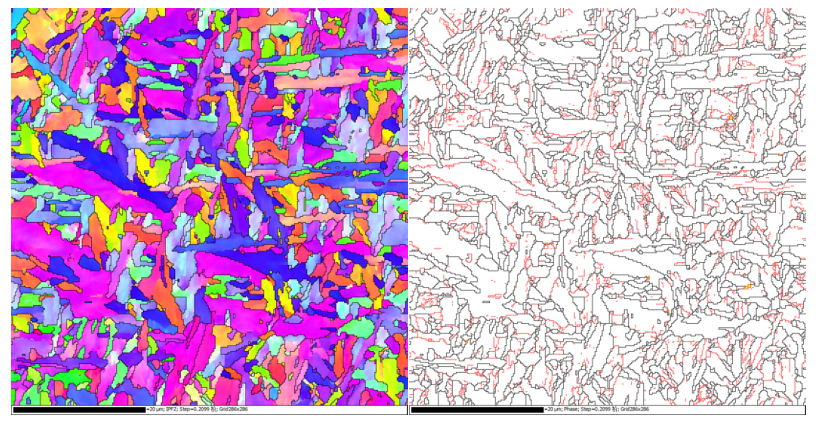

在本研究中,在末道焊缝切取厚度为0.35mm的均匀薄片,在砂纸上将试样磨至35~40mm厚,然后将薄片冲成φ3mm的圆片试样。用双喷电解仪将试样中心减薄出小孔,如若试样厚度过大,再用离子减薄仪减薄。本试验采用的磁力减薄器型号为MTP-1A,采用减薄溶液为6%的高氯酸乙醇溶液,电压为25V,电流为60mA,溶液温度为-25℃。制备完成后,用酒精冲洗干净后,采用Zeiss Merlin扫描电子显微镜EBSD功能进行扫描,分析观察亚结构板条尺寸与分布、晶粒度、有效晶粒尺寸等。

In this study, homogeneous slices with thickness of 0.35mm were cut at the last weld, the sample was ground to 35~40mm thickness on sandpaper, and then the slices were washed into φ3mm circular sample. Double-jet electrolysis instrument will be used to thin the sample center out of small holes, if the sample thickness is too large, then use ion thinning instrument to thin. In this test, the magnetic thinning device type is MTP-1A, and the thinning solution is 6% perchlorate ethanol solution, the voltage is 25V, the current is 60mA, and the solution temperature is -25℃. After the preparation, clean with alcohol, Zeiss Merlin scanning electron microscope EBSD function was used to scan, analyze and observe the size and distribution of substructure lath, grain size, effective grain size, etc.