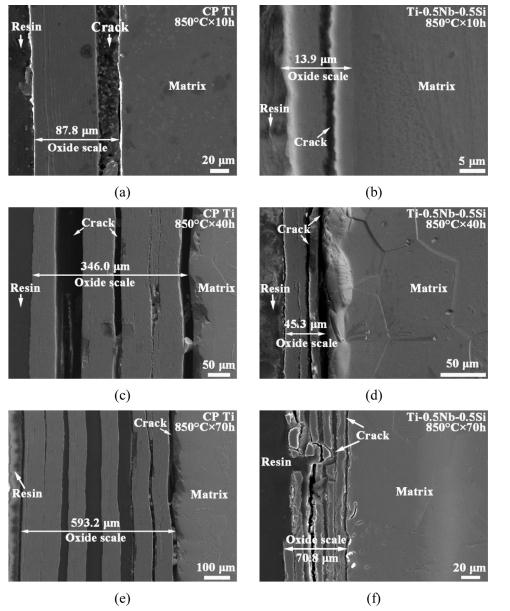

The sample preparing procedure only keeps the remained scale attached to the Ti matrix forCP Ti in this figure In contrast, no peeling-off of the whole scales happens in the scale of the alloy. At 850 °C for 10 h, a large region of the oxide scale is separated from the matrix by wide and deep cracking, letting resin for sample making fill into cracks between the oxide scale and the matrix (Fig. a). It shows a strong tendency for exfoliation of the whole scale. However, the cracking in the scale of the alloy at the same condition is much less serious (Fig. b). At 850 °C for 40 h, the remained scale on CP Ti is divided into three layers due to cracking (Fig. c), while those on the alloy is divided into two layers (Fig. d). At 850 °C for 70 h, the remained scale on CP Ti is divided into five layers (Fig. e), while the scale of the alloy is also divided into five layers with locally spalling (Fig. f). Throughout the oxidation process, cracking is much less se-vere in the scale of the alloy.

The sample preparing procedure only keeps the remained scale attached to the Ti matrix forCP Ti in this figure In contrast, no peeling-off of the whole scales happens in the scale of the alloy. At 850 °C for 10 h, a large region of the oxide scale is separated from the matrix by wide and deep cracking, letting resin for sample making fill into cracks between the oxide scale and the matrix (Fig. a). It shows a strong tendency for exfoliation of the whole scale. However, the cracking in the scale of the alloy at the same condition is much less serious (Fig. b). At 850 °C for 40 h, the remained scale on CP Ti is divided into three layers due to cracking (Fig. c), while those on the alloy is divided into two layers (Fig. d). At 850 °C for 70 h, the remained scale on CP Ti is divided into five layers (Fig. e), while the scale of the alloy is also divided into five layers with locally spalling (Fig. f). Throughout the oxidation process, cracking is much less se-vere in the scale of the alloy.