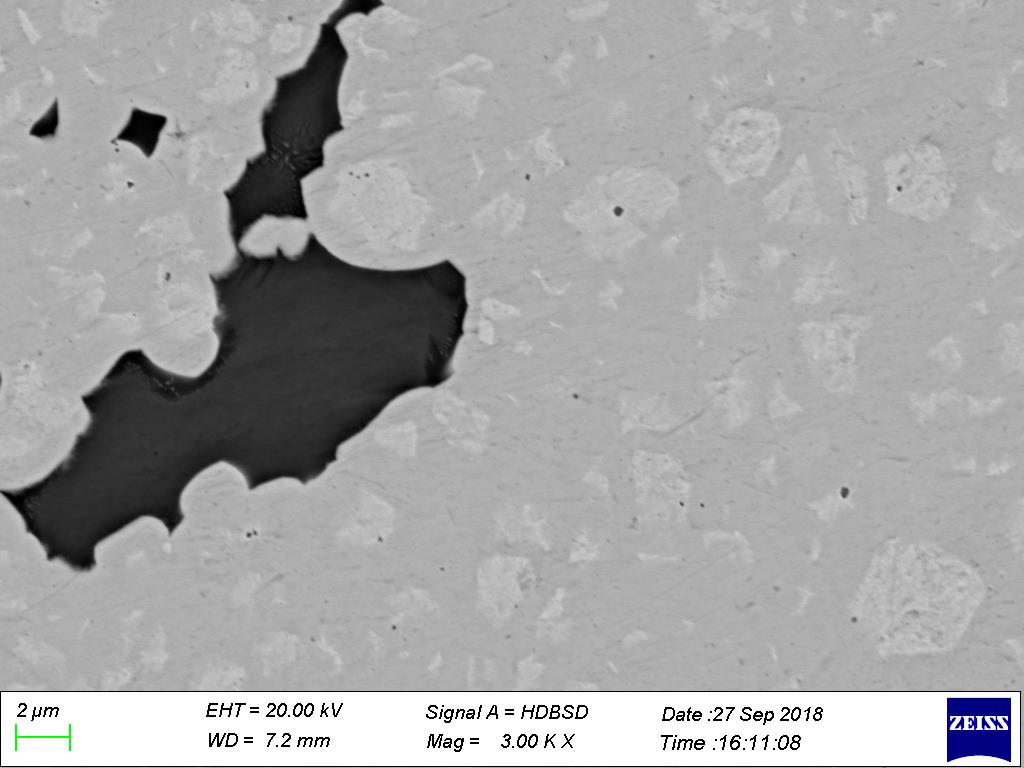

取称量后的超高纯W及高纯Ti/TiH2粉末,放入混合了一定比例钨球的V型混料机进行均匀混料,物料以钛箔包裹后置于石墨模具,在真空热压炉内开展高温高压烧结试验。选取烧结温度1400℃、压力25MPa、保温时间60min,并在700 ℃时保温3.5h。通过带有背散射电子成像的场发射电子扫描电镜(SEM)观察合金的微观组织。其中SEM加速电压15-20KV,放大倍数500-3000×,通过样品的SEM显微组织,分析样品的第二相分布。

After weighing, ultra-pure W and high-pure Ti/TiH2 powders were put into a V-shaped mixer mixed with a certain proportion of tungsten spheres for uniform mixing. The materials were wrapped with titanium foil and placed in a graphite mold to carry out high-temperature and high-pressure sintering test in a vacuum hot pressing furnace. Sintering temperature 1400℃, pressure 25MPa, holding time 60min, and holding time 3.5h at 700 ℃ were selected. The microstructure of the alloy was observed by field emission electron scanning electron microscopy (SEM) with backscattered electron imaging. The SEM acceleration voltage is 15-20kV and the amplification factor is 500-3000×. The second phase distribution of the sample is analyzed by SEM microstructure.