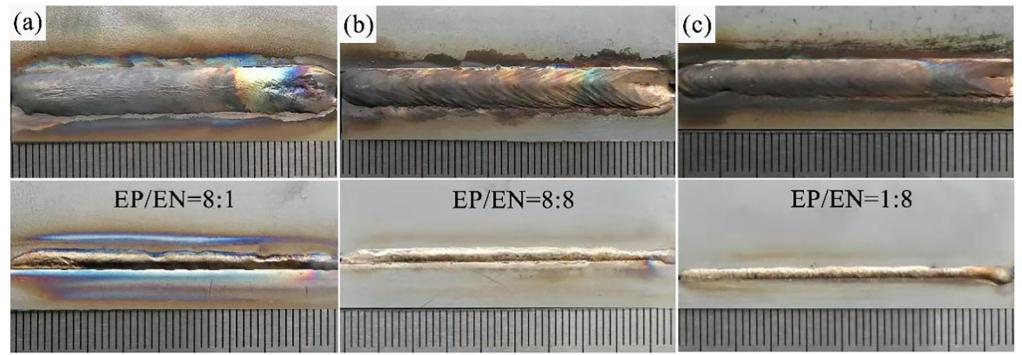

The figure shows weld seams with different EP/EN ratios. The front and back of the seams are smooth and the seam toes are continuous, indicat-ing that the seam geometry is acceptable. Because of the decreasing thermal applied on the base metals, the melting pool cannot spread ef-fectively on the surface, and the seam width decreases with the EP/EN ratio.

The figure shows weld seams with different EP/EN ratios. The front and back of the seams are smooth and the seam toes are continuous, indicat-ing that the seam geometry is acceptable. Because of the decreasing thermal applied on the base metals, the melting pool cannot spread ef-fectively on the surface, and the seam width decreases with the EP/EN ratio.