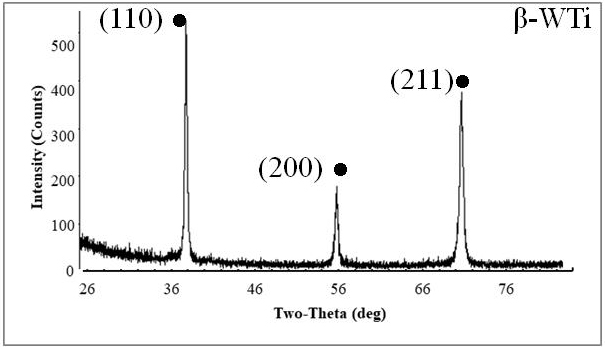

取称量后的超高纯W及高纯Ti/TiH2粉末,放入混合了一定比例钨球的V型混料机进行均匀混料,物料以钛箔包裹后置于石墨模具,在真空热压炉内开展高温高压烧结试验,烧结温度1200~1600℃、加压压力0~35MPa、保压保温时间30~120min,分析其中工艺参数对合金致密度及微观组织的影响,获取钨合金靶材理想的相组成结构。

After weighing, ultra-pure W and high-pure Ti/TiH2 powders were put into a V-type mixer mixed with a certain proportion of tungsten spheres for uniform mixing. The materials were wrapped with titanium foil and placed in a graphite mold, and sintering tests were carried out at high temperature and high pressure in a vacuum hot pressing furnace. The sintering temperature is 1200~1600℃, the pressure is 0~35MPa, and the pressure holding time is 30~120min. The effect of process parameters on the density and microstructure of tungsten alloy is analyzed, and the ideal phase composition structure of tungsten alloy target is obtained.