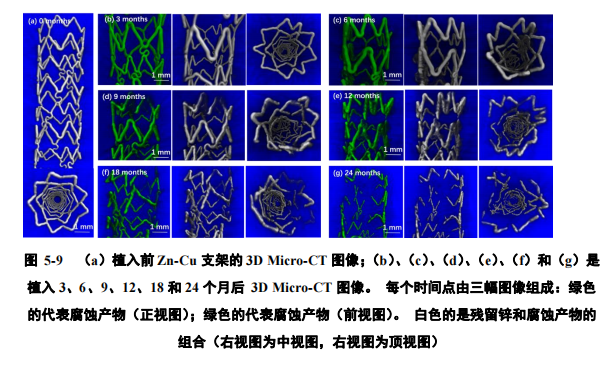

图 5-9(a)为植入前 Zn-Cu 支架的 Micro-CT 3D 重建图像。图 5-9(b)显示,锌铜支架在植入后的前 3 个月内降解相当均匀,没有局部腐蚀产物的积累;在图 5-9

(b)-(d)中均可以看到致密的连续腐蚀层,这意味着植入 9 个月后,主要的腐蚀类型仍然是均匀腐蚀;图 5-9(c)是支架植入 6 个月后的重建图像,可见锌铜支架在植入后 6 个月时仍然保持机械完整性,但是在这个时间点上,可以发现支柱中的一些局部腐蚀位置。在植入 9 个月后(图 5-9(d)),支架杆的弯曲处开始发生断裂。到第 12 个月,支架结构已经发生严重解体(图 5-9(e)),此时几乎没有完整的支持单元存在,表明支架已经彻底丧失支撑功能。然而,支架支撑结构的瓦解同时也代表支架对血管束缚作用的解除,这是可降解支架植入后发生血管正向重构的前提条件。(a)植入前 Zn-Cu 支架的 3D Micro-CT 图像;(b)、(c)、(d)、(e)、(f)和(g)是 植入 3、6、9、12、18 和 24 个月后 3D Micro-CT 图像。 每个时间点由三幅图像组成:绿色的代表腐蚀产物(正视图);绿色的代表腐蚀产物(前视图)。 白色的是残留锌和腐蚀产物的组合(右视图为中视图,右视图为顶视图) .

Figure 5-9(a) shows the 3D Micro-CT reconstruction image of the Zn-Cu stent before implantation. Figure 5-9(b) shows that the zinc-copper stent degrades fairly uniformly within the first 3 months after implantation, and there is no accumulation of local corrosion products; in Figure 5-9

A dense continuous corrosion layer can be seen in (b)-(d), which means that 9 months after implantation, the main type of corrosion is still uniform corrosion; Figure 5-9(c) shows 6 stents implanted In the reconstructed image after one month, it can be seen that the zinc-copper stent still maintains mechanical integrity 6 months after implantation, but at this point in time, some local corrosion locations in the pillar can be found. Nine months after implantation (Figure 5-9(d)), the bending of the stent rod began to break. By the 12th month, the stent structure had been severely disintegrated (Figure 5-9(e)). At this time, there was almost no complete support unit, indicating that the stent had completely lost its supporting function. However, the collapse of the stent support structure also represents the release of the stent's binding effect on the blood vessel, which is a prerequisite for the positive remodeling of the blood vessel after the implantation of the degradable stent. (A) 3D Micro-CT image of Zn-Cu stent before implantation; (b), (c), (d), (e), (f) and (g) are implanted 3, 6, 9, 12 3D Micro-CT images after 18 and 24 months. Each time point is composed of three images: green represents corrosion products (front view); green represents corrosion products (front view). The white one is the combination of residual zinc and corrosion products (the right view is the middle view and the right view is the top view).