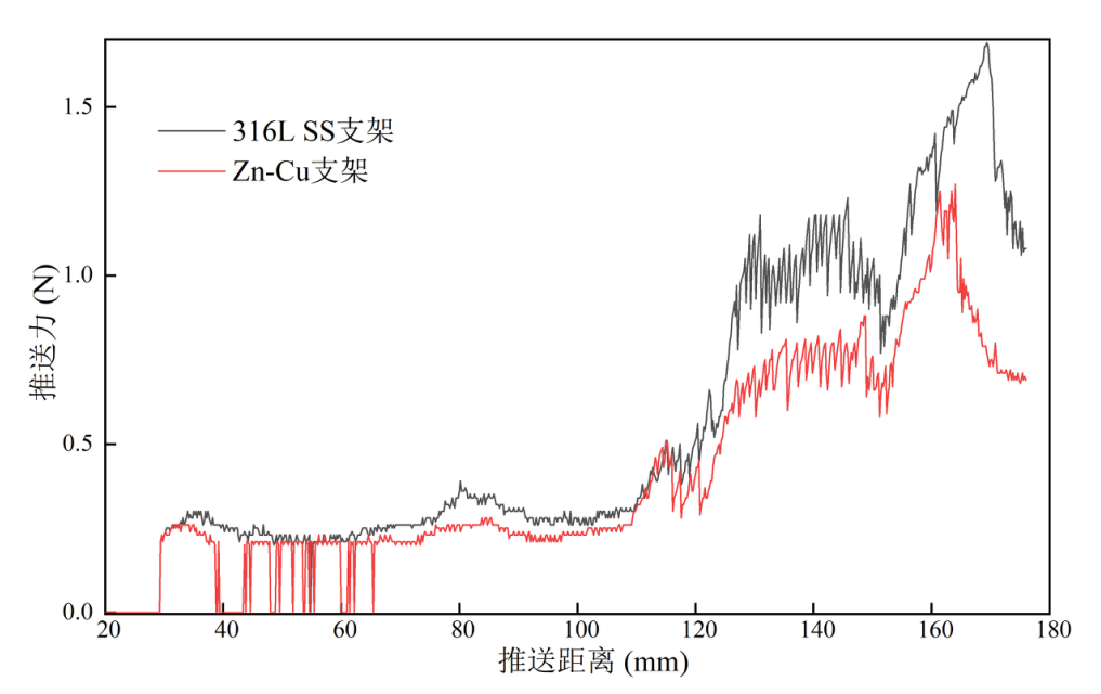

图4-18为Zn-Cu支架和316L SS支架的通过性曲线。两组支架采用了相同的壁厚、花型设计、压握加工参数和输送系统,因此两者的推送曲线可以比较真实的反应两者在通过人体血管时的不同情况。在图4-18中,推送力越小,代表支架系统越容易通过弯曲血管。支架系统在行进约130 mm后进入较小的转弯半径,推送力开始显著升高;316L SS支架在行进距离超过130 mm后大部分行程中的推送力大于1 N;Zn-Cu支架仅在行进距离达到160 mm处时短暂大于1 N,显示了其在血管模型中通过所受到的阻力较小。Zn-Cu支架在通过血管模型过程中出现的峰值推力为1.21±0.09 N,316L SS支架在通过血管模型过程中出现的峰值推力为1.73±0.11 N,通过血管模型时的峰值推力为后者的69.9%,说明由于Zn-Cu材料相比不锈钢而言较低的屈服强度也给Zn-Cu支架带来一定的正面影响。

Figure 4-18 shows the passing curve of Zn-Cu stent and 316L SS stent. The two sets of stents use the same wall thickness, pattern design, crimping processing parameters and delivery system, so the push curves of the two can be compared to reflect the different situations of the two when they pass through the human blood vessels. In Figure 4-18, the smaller the pushing force, the easier it is for the stent system to pass through curved blood vessels. The stent system enters a smaller turning radius after traveling about 130 mm, and the pushing force begins to increase significantly; the 316L SS stent has a pushing force greater than 1 N in most of its strokes after the travel distance exceeds 130 mm; the Zn-Cu stent is only traveling When the distance reaches 160 mm, it is temporarily greater than 1 N, which shows that the resistance to passing through the blood vessel model is relatively small. The peak thrust of the Zn-Cu stent during the passage through the blood vessel model is 1.21±0.09 N, and the peak thrust of the 316L SS stent during the passage through the blood vessel model is 1.73±0.11 N, and the peak thrust when passing through the blood vessel model is the latter's 69.9%, indicating that the lower yield strength of Zn-Cu material compared to stainless steel also has a positive effect on the Zn-Cu stent.