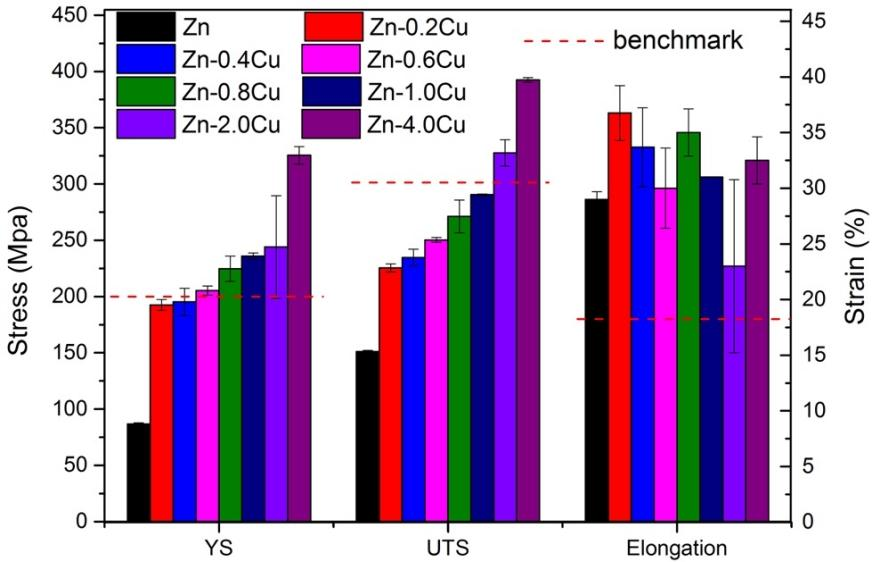

图3-8可见,随着Cu含量的增加,轧态合金的屈服强度(YS)和抗拉强度(UTS)显著增加。轧态Zn-4.0Cu合金的屈服强度和抗拉强度分别达到326 MPa和393 MPa。当铜含量达到0.6wt.%时,合金的屈服强度即可超过benchmark,达到210 MPa。然而,当铜含量超过2wt.%时,抗拉强度才超过benchmark。纯锌和锌铜合金的伸长率也从铸态的1.7%~5.8%提高到轧态下的23%~37%。本部分研究中,在轧制压下率达到90%的情况下,即使纯锌的伸长率也超过了benchmark所要求的15%。本研究的轧制工艺下得到的轧态样品中,低百分比铜元素的加入都或多或少的提高了合金的伸长率,其中Zn-0.2Cu和Zn-0.8Cu的伸长率表现最为优异,分别达到了37%和35%。然而,在铜含量高于2wt.%后,材料的伸长率反而略有下降。这可能是由于脆性第二相出现导致的。

Figure 3-8 shows that with the increase of Cu content, the yield strength (YS) and tensile strength (UTS) of the rolled alloy increase significantly. The yield strength and tensile strength of the rolled Zn-4.0Cu alloy reached 326 MPa and 393 MPa, respectively. When the copper content reaches 0.6wt.%, the yield strength of the alloy can exceed the benchmark and reach 210 MPa. However, when the copper content exceeds 2wt.%, the tensile strength exceeds the benchmark. The elongation of pure zinc and zinc-copper alloys has also increased from 1.7% to 5.8% in the as-cast state to 23%-37% in the as-rolled state. In this part of the study, when the rolling reduction rate reaches 90%, even the elongation of pure zinc exceeds the 15% required by the benchmark. In the rolled samples obtained under the rolling process in this study, the addition of low percentage copper element more or less increased the elongation of the alloy, and the elongation of Zn-0.2Cu and Zn-0.8Cu was the best Excellent, reaching 37% and 35% respectively. However, when the copper content is higher than 2wt.%, the elongation of the material drops slightly. This may be caused by the appearance of a brittle second phase .