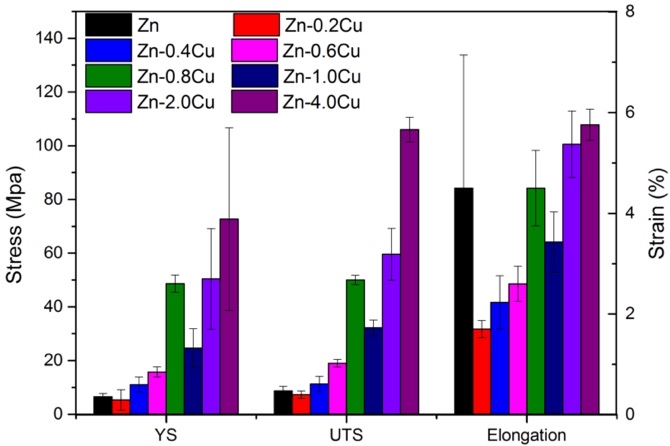

图3-7显示,铸态下材料的力学性能不稳定(样本间标准差大),可能是由于材料本身组织的均匀性较差。但总体趋势可见铜的加入无论对材料抗拉强度、屈服强度和伸长率都具有显著的改善,使材料的抗拉强度和屈服强度分别达到约70 MPa和约110 MPa。与铜元素加入对轧态合金硬度的影响不同,力学强度数据的突变发生在铜含量达到0.8wt.%时。铜的加入铸态合金伸长率有所提高,但改善并不明显,4wt.%Cu的伸长率也低于6%。

Figure 3-7 shows that the mechanical properties of the material in the as-cast state are unstable (the standard deviation between samples is large), which may be due to the poor uniformity of the material itself. However, the overall trend shows that the addition of copper can significantly improve the tensile strength, yield strength and elongation of the material, making the tensile strength and yield strength of the material reach about 70 MPa and about 110 MPa, respectively. Unlike the effect of copper addition on the hardness of the rolled alloy, the sudden change in the mechanical strength data occurs when the copper content reaches 0.8wt.%. The elongation of the as-cast alloy is increased by the addition of copper, but the improvement is not obvious. The elongation of 4wt.%Cu is also less than 6%.