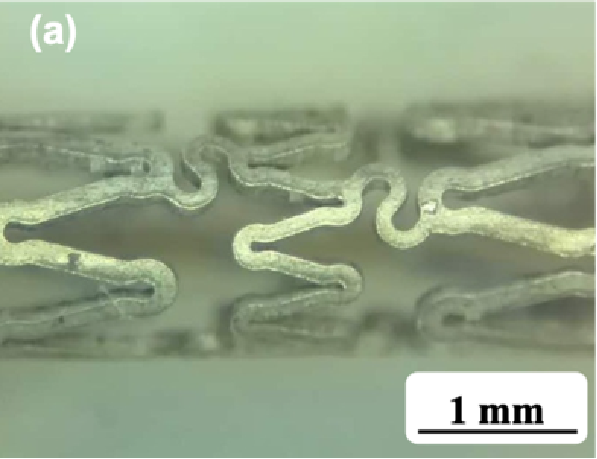

图4-13显示了激光切割、酸洗和化学抛光工艺后支架的表面形貌:使用Zn-0.8Cu微管可以制备出杆宽均匀、形态完整的支架,且Zn-Cu支架表面形貌可以通过酸洗和抛光改善。飞秒激光雕刻后(图4-13(a))即可以呈现出较为完整的支架设计花型,支架杆边缘没有烧蚀等热影响区域出现;支架杆之间残留碎屑较少,可通过简单的超声、酸洗去除;化学抛光后(图4-13(c))支架杆由于激光切割带来的锐利边缘得到改善,且达到镜面效果。支架杆边缘圆滑过渡有利于避免应力集中和减少对血管组织的刺激。图4-13表明,Zn-Cu支架具有可抛光性,具备加工成为冠脉支架终产品的基本要求。

Figure 4-13 shows the surface morphology of the stent after laser cutting, pickling and chemical polishing: the use of Zn-0.8Cu microtubes can prepare a stent with uniform rod width and complete morphology, and the surface morphology of the Zn-Cu stent can be Improved by pickling and polishing. After femtosecond laser engraving (Figure 4-13(a)), a relatively complete stent design pattern can be presented. There is no heat-affected area such as ablation on the edge of the stent rod; there is less residual debris between the stent rods, which can pass through Simple ultrasonic and pickling removal; after chemical polishing (Figure 4-13(c)) the sharp edges of the stent rod due to laser cutting are improved, and the mirror effect is achieved. The smooth transition of the edge of the stent rod is beneficial to avoid stress concentration and reduce irritation to the vascular tissue. Figure 4-13 shows that the Zn-Cu stent is polishable and has the basic requirements for processing into the final product of the coronary stent.