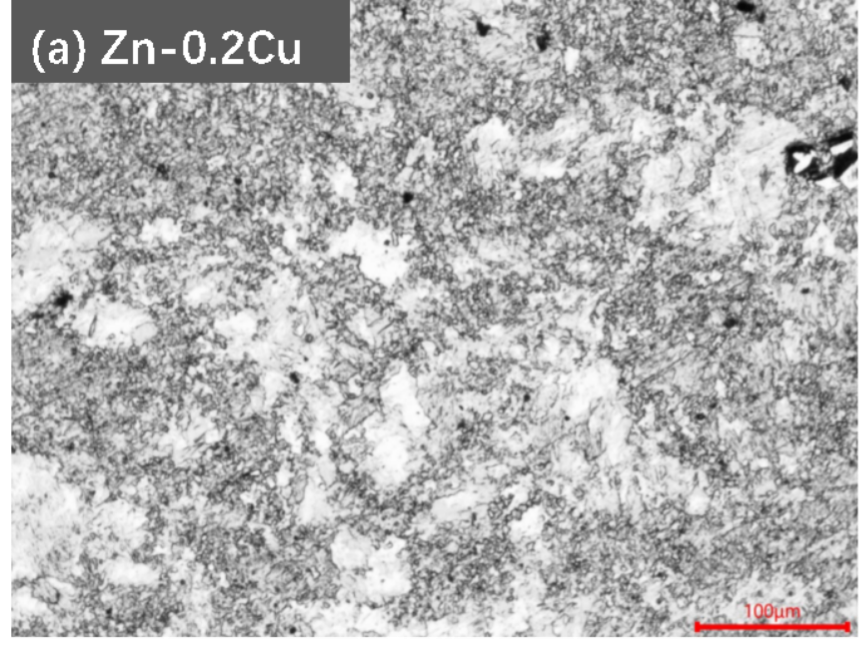

图3-5可见,轧制后各种铜含量的合金组织晶粒均得以细化。晶粒细化和有利于材料力学性能的提升。在多晶体中,屈服强度是与滑移由一个晶粒转移到另一个晶粒紧密相关的。晶粒越大,晶界处位错塞积群中的位错数越多,由此引起的附加应力越大,易使临近的晶粒位错源开动,引起屈服,所以屈服强度越低。晶粒越小,单位体积中晶粒的数量越多,含晶界的面积越大, 形变的抗力越大。图3-5还显示,轧制后枝晶ε相发生了一定程度的断裂和伸长动态再结晶,形成了等轴晶。围绕枝晶CuZn5相附近的暗色区域,可见大量晶粒尺寸远小于其它区域的细晶区域。

Figure 3-5 shows that the grains of the alloy structure with various copper contents can be refined after rolling. Refinement of grains is conducive to the improvement of mechanical properties of materials. In polycrystals, the yield strength is closely related to the transfer of slip from one grain to another. The larger the grain, the more the number of dislocations in the dislocation cluster at the grain boundary, and the greater the additional stress caused by this, which is likely to cause the adjacent grain dislocation sources to activate and cause yield, so the yield strength is lower. The smaller the crystal grains, the greater the number of crystal grains per unit volume, the larger the area containing the grain boundaries, and the greater the resistance to deformation. Figures 3-5 also show that the dendritic epsilon phase undergoes a certain degree of fracture and elongation dynamic recrystallization after rolling, forming equiaxed crystals. Surrounding the dark region near the dendritic CuZn5 phase, a large number of fine-grained regions with a size much smaller than other regions can be seen.