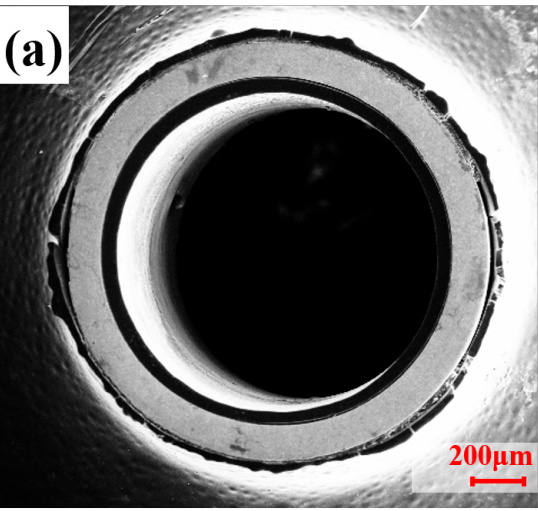

微管的径向、轴向切面SEM图如图4-10所示。其中(a)、(b)、(c)为横切面图像,(d)、(e)、(f)为纵切面图像,(c)和(d)中的插图分别给出了第二相颗粒的EDS分析结果。管坯经过约12道次的冷拔,其壁厚从1 mm降低到127 μm,压下率达到87.3%。图4-10可见,经过大变形量的塑性形变,第二相颗粒直径减小至直径1 μm以下,弥散分布于锌基底中。

The SEM images of the radial and axial sections of the microtubes are shown in Figure 4-10. Among them, (a), (b), (c) are cross-sectional images, (d), (e), (f) are longitudinal images, and the illustrations in (c) and (d) respectively show the second phase EDS analysis results of the particles. After about 12 passes of cold drawing, the wall thickness of the tube blank was reduced from 1 mm to 127 μm, and the reduction rate reached 87.3%. Figure 4-10 shows that after a large amount of plastic deformation, the diameter of the second phase particles is reduced to less than 1 μm in diameter, and they are dispersed in the zinc substrate.