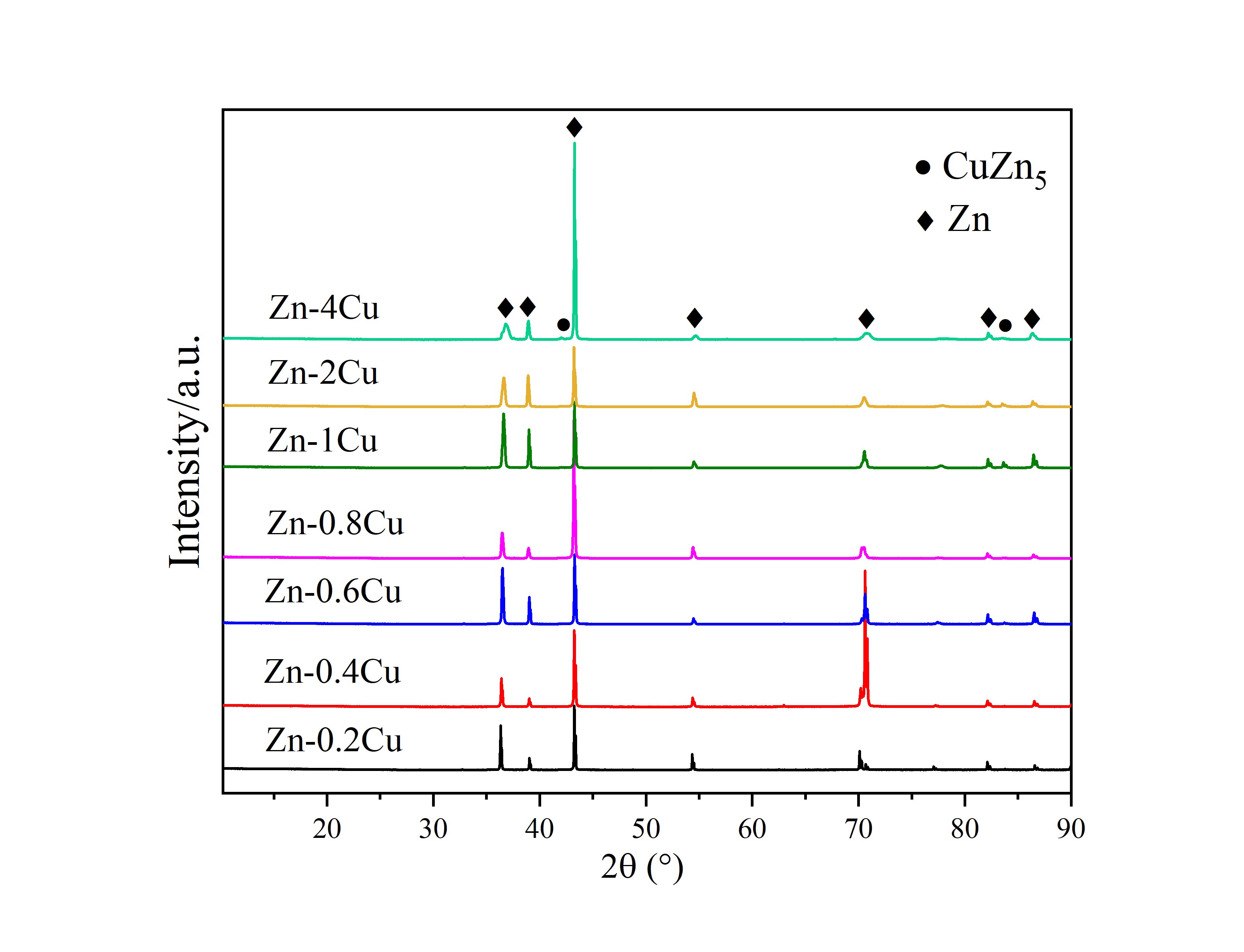

XRD结果显示,轧态锌铜合金主要由Zn基体和CuZn5相组成。 根据锌铜合金相图,室温下Cu元素在Zn基底中有0.3wt.%的固溶度。当Cu含量低于0.3wt.%时,理论上锌铜合金可以以Zn(Cu)置换固溶体单相的形式存在,少量第二相CuZn5的出现是发生非平衡凝固过程的结果。 合金最终成分为Zn(Cu)固溶体+ε(CuZn5),且ε相随Cu含量增多而增多。 图3-3可见,当Cu含量逐渐增高到1%时,XRD图谱中开始明显出现较为明显的CuZn5特征峰,CuZn5特征峰随着Cu含量提高而提高。已有报道对铸态Zn-1Cu、Zn-2Cu、Zn-3Cu、Zn-4Cu样品的XRD分析都得到了类似结果,即随着Cu元素含量的提高,合金中CuZn5的含量也在提高。

XRD results show that the rolled zinc-copper alloy is mainly composed of Zn matrix and CuZn5 phase. According to the zinc-copper alloy phase diagram, Cu element has a solid solubility of 0.3wt.% in the Zn substrate at room temperature. When the Cu content is less than 0.3wt.%, theoretically the zinc-copper alloy can exist in the form of a single phase of Zn (Cu) replacement solid solution, and the appearance of a small amount of second phase CuZn5 is the result of the non-equilibrium solidification process. The final composition of the alloy is Zn (Cu) solid solution + ε (CuZn5), and the ε phase increases with the increase of Cu content. As shown in Figure 3-3, when the Cu content gradually increases to 1%, the XRD pattern begins to clearly show the characteristic peak of CuZn5, and the characteristic peak of CuZn5 increases with the increase of Cu content. It has been reported that the XRD analysis of the as-cast Zn-1Cu, Zn-2Cu, Zn-3Cu, and Zn-4Cu samples have all obtained similar results, that is, as the content of Cu element increases, the content of CuZn5 in the alloy also increases.