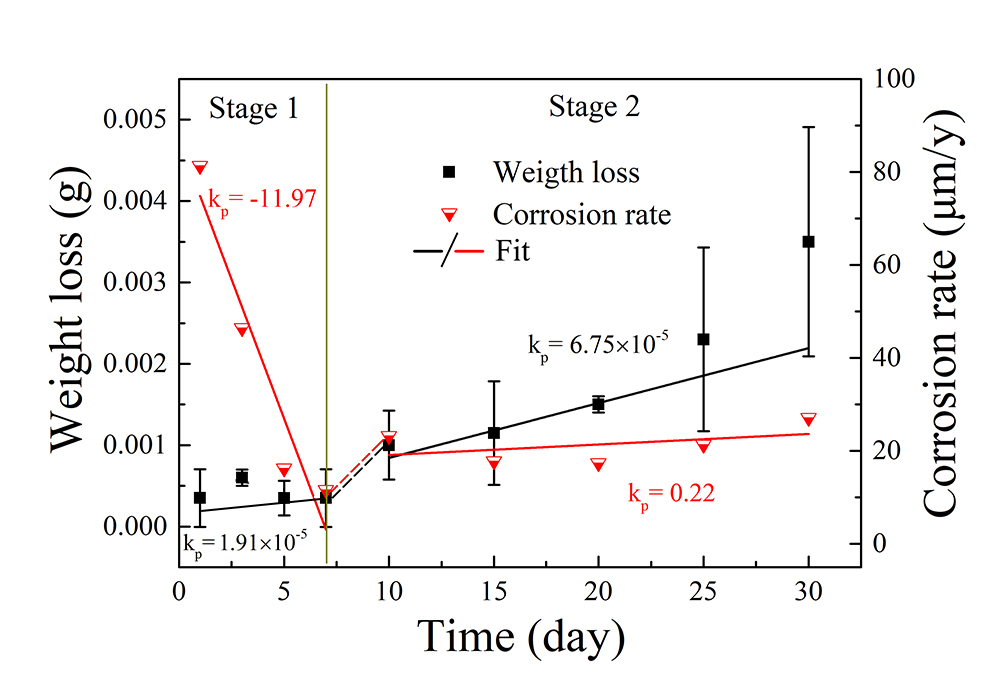

重量损失和相应的腐蚀速率(CRw)(图 8(a))进一步表明合金的两阶段腐蚀。在第 1 阶段,前 7 天内未观察到体重减轻的明显增加,kp 值为 1.91 × 10−5g/天。然后由 kpvalue 表示的失重率在第 30 天增加到 6.75 × 10−5g/day,表明合金在第 2 阶段发生点蚀/局部腐蚀。相应的 CRw(图 8(a))从 81 微米,下降第 1 天的至第 7 天的 16 微米/年,这是由于腐蚀产物的覆盖抑制了表面合金的活性。之后,腐蚀速率在 30 天内波动大约 20 微米/年。如图8(b)所示,在第1阶段,kpvalue占优势的Zn2+释放速率为0.03 mg L−1 day 1,在第2阶段后加速至0.08 mg L−1day−1。合金上腐蚀坑的最大深度和相应的 CR 也分别测量和计算(图 8(c))。 腐蚀坑的最大深度从第 5 天的 8 μm 增加到第 30 天的 60 μm。同时,CRpin 从第 5 天的 25μm/年快速增加到第 15 天的 54μm/年,然后稳步增加到第 60 天/年 30,表明点蚀/局部腐蚀在浸泡中期开始和发展。

Weight loss and the corresponding corrosion rate (CRw) (Fig. 8(a)) further indicate a two-stage corrosion of the alloy. At stage 1, no obvious increase of weight loss can be observed within first 7 days with kpvalue of 1.91 × 10−5g/day. Then the weight loss rate indicated by kpvalue increases to 6.75 × 10−5g/day within day 30, indicating the pitting/localized corrosion happen on alloy at stage 2. The corresponding CRw(Fig. 8(a)) plunges from 81μm /year at day one to 16μm /year at day 7 during stage 1,resulting from the coverage of corrosion products which suppress the activity of surface alloy. Afterwards, the corrosion rate fluctuates around 20 μm/year within 30 days.As depicted in Fig. 8(b), Zn2+release rate prevailed by kpvalue is 0.03 mg L−1day−1 within the stage 1, which accelerates to be 0.08 mg L−1day−1 afterwards at stage 2.The max depth of corrosion pits on alloy and the corresponding CR pare also measured and calculated (Fig. 8(c)), respectively. The max depth of corrosion pits increases from 8 μm at day 5 up to 60 μm at day 30. Meanwhile, the CRpincreases quickly from 25μm /year at day 5 up to 54μm /year at day 15 then increases steadily to 60μm /year at day 30, indicating that the Pitting/localized corrosion initials and develops during middle period of immersion.