去除腐蚀产物后对合金表面的进一步观察(图7)表明,随着浸泡时间的延长,非均匀腐蚀变得更加明显。腐蚀的合金表面在第一天是均匀的(图7(a)),然后腐蚀坑随着时间的推移而繁殖和生长(图7(b-h))。在×50,000放大倍数下的观察显示,腐蚀优先发生在晶界(GBs)(图7(a1)和(b1)),因为它们的能量高于颗粒内区。GB腐蚀随着浸泡时间的延长而扩展,消耗相邻晶粒(图7(e1-g1))。如图7(g1)中蓝色虚线所示,几个相邻的腐蚀GB区域可以合并成一个大坑。此外,从第5天开始检测到直径为158±80纳米的微孔(图7(c1-h1)),这加速了腐蚀过程。

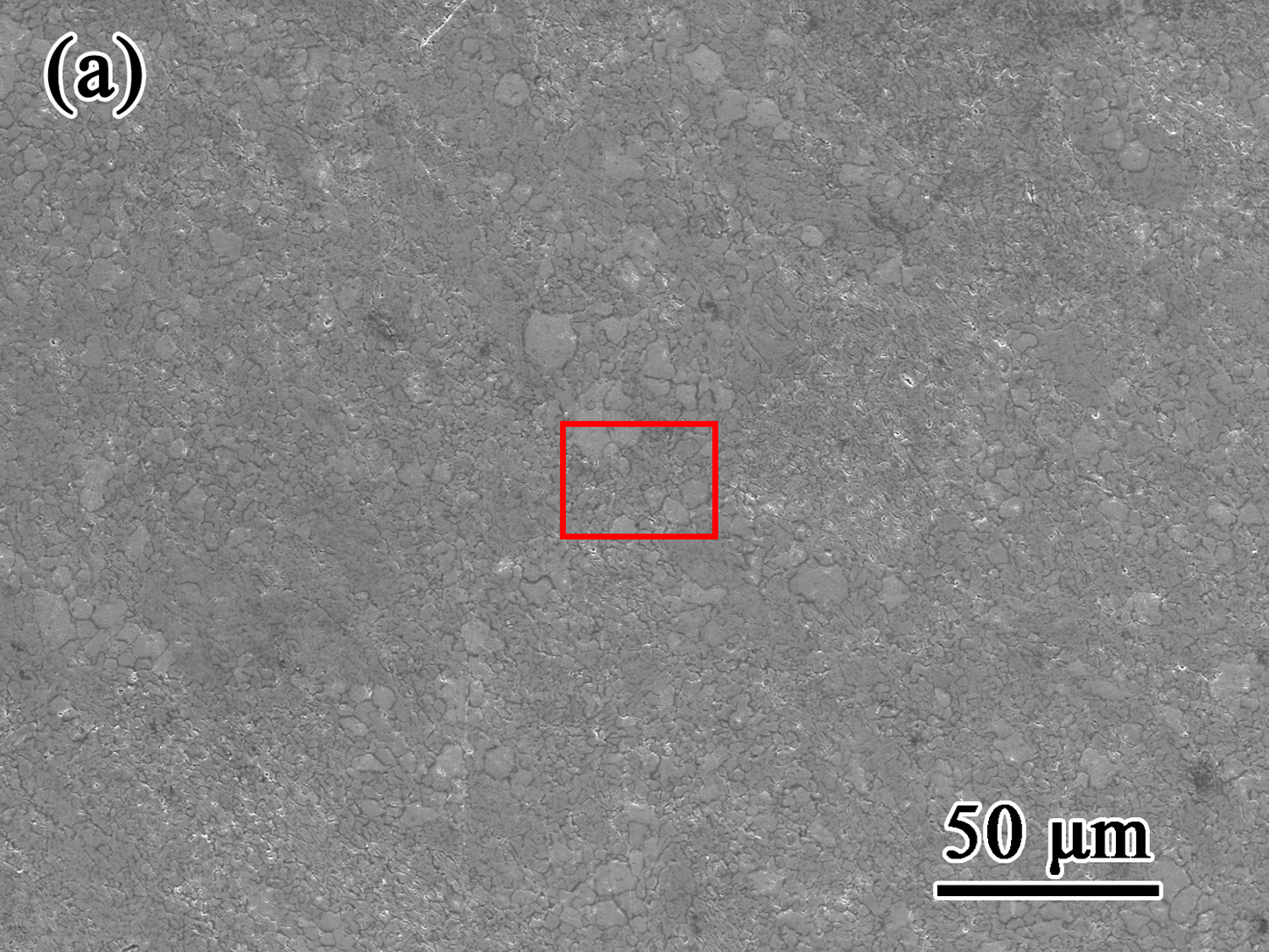

Further observation on alloy surfaces (Fig. 7) after removal of corrosion products shows that non-uniform corrosion becomes more obvious with immersion time. The corroded alloy surface is uniform at day one (Fig. 7(a)), then corrosion pits multiply and grow with time (Fig. 7(b–h)). Observation at ×50,000 magnification reveals that the corrosion happens preferentially at grain boundaries (GBs) (Fig. 7(a1) and (b1)), due to their higher energies than intragranular regions. The GB corrosion expands with immersion time, consuming adjacent grains (Fig. 7(e1-g1)). Several neighboring corroded GB areas can merge into a large pit, a outlined by blue dotted line in Fig. 7(g1). Besides, micro-pores of 158 ± 80 nm in diameter are detected from day 5 (Fig. 7(c1-h1)), which accelerate the corrosion process.