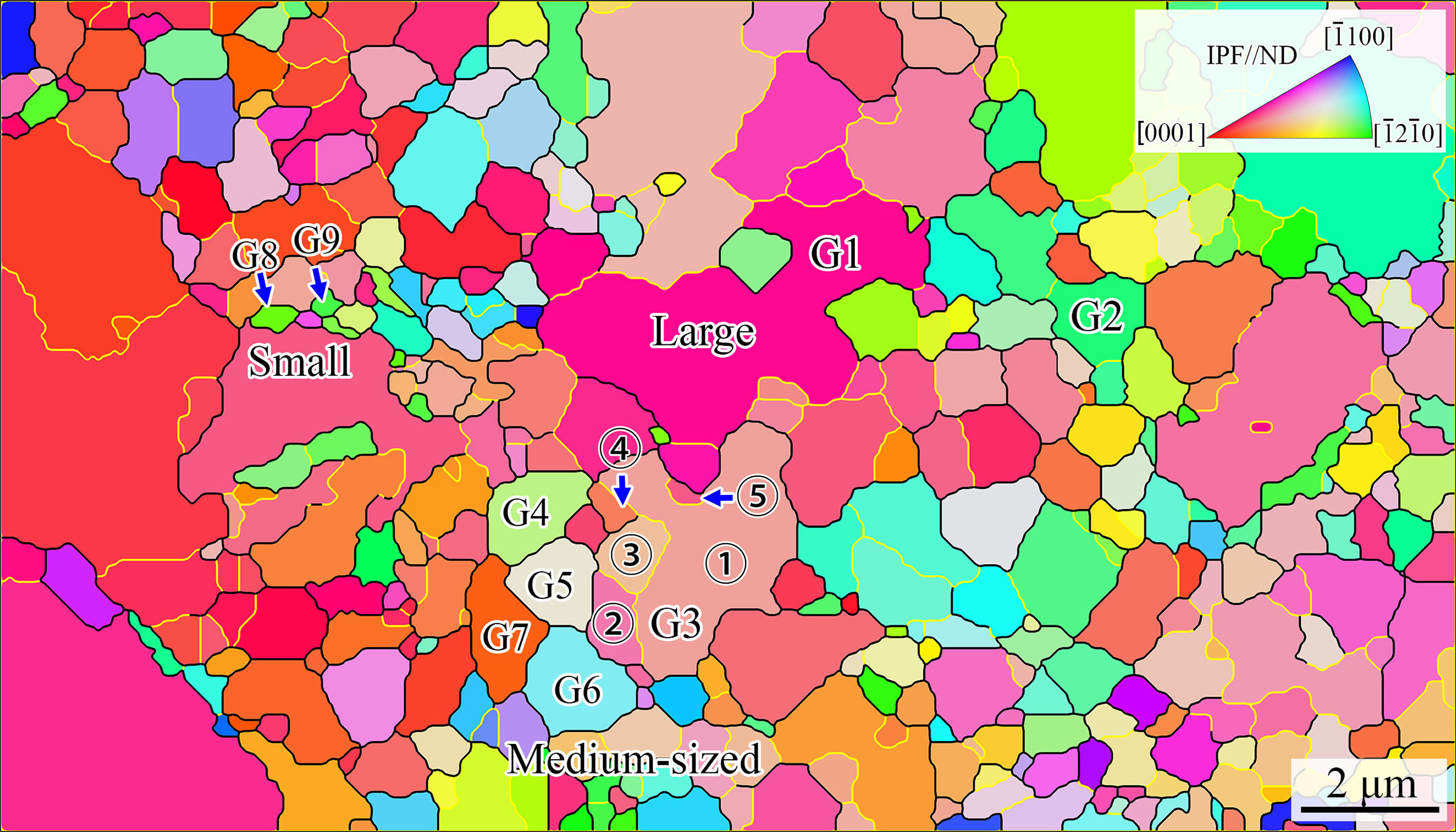

T-EBSD 测量的 Zn 带的微观结构如图 3(a)所示。 其相应的晶粒尺寸分布在表 2 中进行了统计分析。图 3(a)中被取向错误大于 15°的边界包围的总共 154 个晶粒可以根据它们的尺寸分为三组。 其中当量直径< 1 μm、面积< 0.8μm 2的小颗粒115个,占74.7%,占多数。 其中36个为中等直径ε[1,5] μm,面积ε[0.8,19.6] μm 2,占23.4%。 其余的都是当量直径 > 5μm 和面积 > 19.6μm 2 的大的。许多中、大尺寸的晶粒包含若干个亚晶粒,这些亚晶粒被取向误差大于 5°的边界所包围。 如图 3(a)所示,大粒 G1 含有 10 多个亚粒,中粒 G2 含有 4 个亚粒,而中粒 G3 含有 5 个亚粒。 也有中等大小的谷物不含亚谷物,例如谷物 G4-G7。 大多数小晶粒不包含亚晶粒,例如晶粒 G8 和 G9。 图 3(a) 共有 326 个亚晶粒。 如表 2 所示,其中 82.2% 为小型,其余为中型。 因此,大多数亚晶粒是亚微米晶粒,与图 4(a)中的 TEM 表征非常吻合。在图 3(b)中,颗粒根据它们的大小着色。 为了准确分析,表 2 的统计数据中排除了属于小和中型边界晶粒,因为它们只是部分测量,给出了它们尺寸的不确定性。 在图 3(b)中很明显,Zn 带具有三峰晶粒结构。晶粒取向扩展 (GOS) 用于确定晶粒是否以合理的 3°标准进行再结晶。 如表 2 所示,93.9% 的小晶粒发生再结晶,而 61.1% 的中等尺寸晶粒发生再结晶。然而,没有大晶粒被再结晶。 这表明WR合金未完全再结晶,导致三峰晶粒结构。 同样如表 2 所示,53.9% 的小晶粒和 55.6% 的中等晶粒是等轴晶粒,表明它们在晶粒再结晶完成后的温轧道次期间没有受到太大的塑性变形。从图 3(c) 中可以看出,晶粒在 ND 周围表现出分裂的基底织构,这是典型的具有不完全结构的 Zn 合金。

The T-EBSD measured microstructure of Zn band is shown in Fig. 3(a). Its corresponding grain size distribution is statistically analyzed in Table 2. The total 154 grains in Fig. 3(a) enclosed by boundaries with misorientations larger than 15◦can be classified into three groups according to their sizes. 115 of them are small ones with equivalent diameters < 1μm and areas < 0.8μm2, which accounts up to 74.7 %, i.e., the majority. 36 of them are medium ones with equivalent diameters ∈ [1,5] μm and areas ∈ [0.8, 19.6] μm2, which accounts for 23.4 %. The rest of them are large ones with equivalent diameters > 5μm and areas > 19.6μm2. Many medium and large sized grains contain several subgrains,which are enclosed by boundaries with misorientations larger than 5◦. As shown in Fig. 3(a), large grain G1 contains more than ten subgrains, medium-sized grain G2 contains four subgrains, while medium sized grain G3 contains 5 subgrains. There are also medium-sized grains contain no subgrains, e.g., grains G4-G7. The majority of the small grains contain no subgrains, e.g., grains G8 and G9. There are 326 subgrains in total in Fig. 3(a). As listed in Table 2, 82.2 % of them are small ones, and the rest are medium ones. So the majority of the subgrains are sub-micron ones, agreeing well with TEM characterization in Fig. 4(a).In Fig. 3(b), the grains are colored according to their sizes. For an accurate analysis, the boundary grains fall into the small and medium ones are excluded in the statistics in Table 2, since they are only partially measured, giving an uncertainty of their sizes. It is clear in Fig. 3(b) that the Zn band has a tri-modal grain structure.Grain orientation spread (GOS) is employed to determine whether a grain is recrystallized with a reasonable criterion of 3◦. As listed in Table 2, 93.9 % of the small grains are recrystallized, while 61.1 % of the medium-sized ones are recrystallized. However, no large grains are recrystallized. This indicates that the WR alloy is incompletely recrystallized, resulting in the tri-modal grain structure. As also listed in Table 2, 53.9 % of the small grains and a comparable 55.6 % of the medium grains are equiaxed ones, indicating that they are not suffered to much plastic deformation during the warm-rolling pass after the grain recrystallization finishes. It can be seen from Fig. 3(c) that the grains exhibit a divided basal texture around ND, which is typical for Zn alloys with an incompletely recrystallized grain structure.