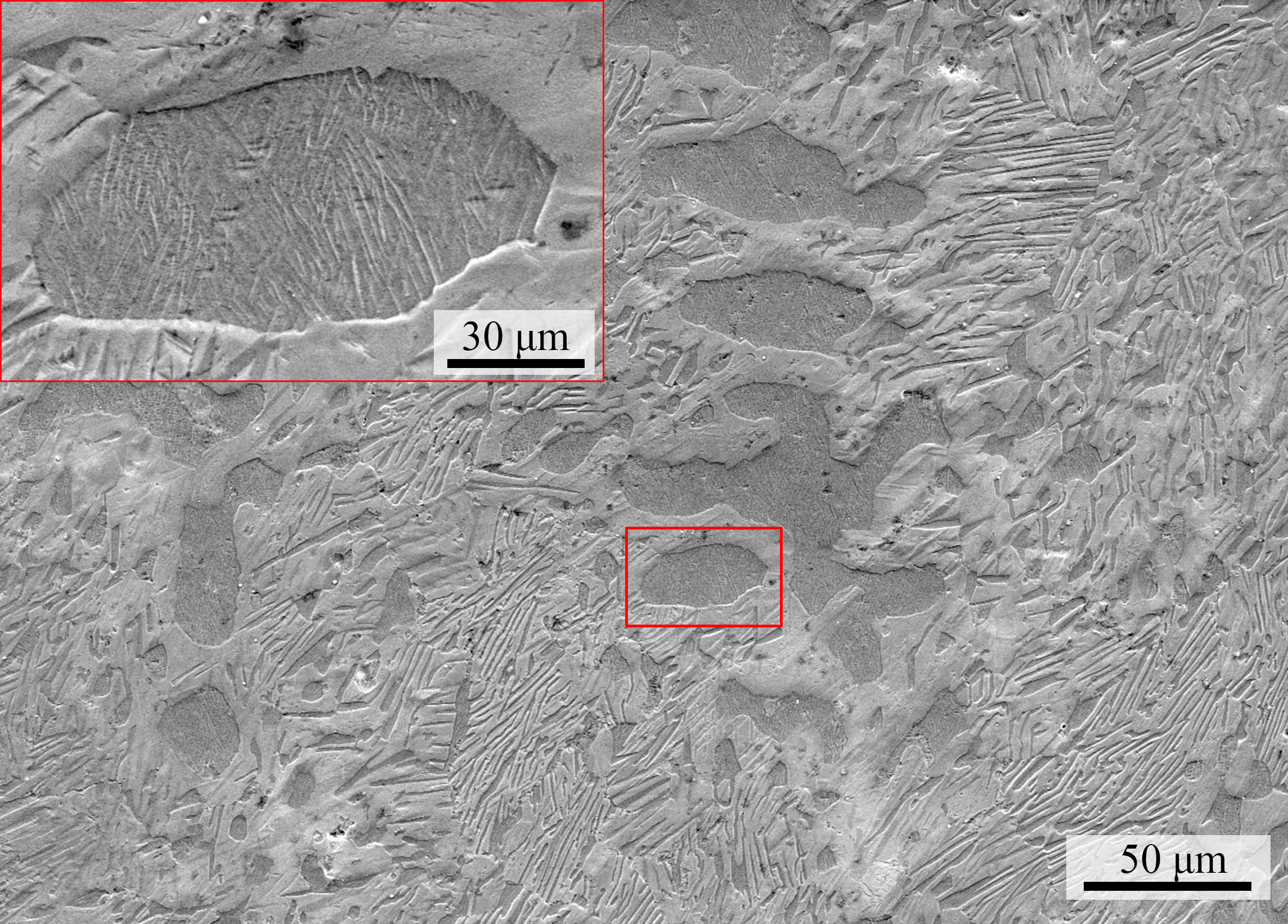

图 2(b)显示了铸态合金的 SEM 显微组织,该合金由枝晶状或椭圆形的初生 β-LiZn4 和 Zn 和 β-LiZn4 的层状共晶组成。 这与过共晶合金成分非常吻合,如图 1(a)所示,过共晶合金成分比 Li 含量的 0.44 重量%(4 原子%)高 0.04 重量%(0.35 原子%)。 仔细观察初级 β-LiZn4,如图 2(b)左角放大的局部区域所示,显示其中有密集的次级 Zn 针。 测得初生β-LiZn4相的硬度为156 ± 6 HV,而共晶相的硬度为87 ± 4 HV。图 2(c)显示了沿 TD 观察的 WR 合金的 SEM 显微组织。 微观结构的特点是交替的 Zn 和 β-LiZn4 带。 通过更大的放大倍数观察到图 2(c) 中的局部区域,如图 2(d) 所示。 可以看出,β-LiZn4 中形成针状二次 Zn,这在 Zn-0.8Li 合金中也得到证实。 Li具有-3.04 V的负标准电极电位,远低于Zn(即-0.76 V),因此β-LiZn4更容易受到蚀刻溶液的侵蚀。 从图 2(b-d) 中可以看出,无论 β-LiZn4 是在初级 β-LiZn4 中还是在共晶中,它总是比周围的 Zn 腐蚀得更快,导致形貌凹陷和颜色更深。如图 2(d) 所示可以看出,β-LiZn4 中形成针状二次 Zn,这在 Zn-0.8Li 合金中也得到证实。 Li具有-3.04 V的负标准电极电位,远低于Zn(即-0.76 V),因此β-LiZn4更容易受到蚀刻溶液的侵蚀。 从图 2(b-d) 中可以看出,无论 β-LiZn4 是在初级 β-LiZn4 中还是在共晶中,它总是比周围的 Zn 腐蚀得更快,导致形貌凹陷和颜色更深。

Fig. 2(b) shows SEM microstructure of the as-cast alloy, which consists of primary β-LiZn4 in a dendrite-like shape or an elliptical shape and laminated eutectic of Zn andβ-LiZn4. This agrees well with the hypereutectic alloy composition, which is 0.04 wt.% (0.35 at.%) higher than the eutectic composition of 0.44 wt.% (4 at.%) in Li content as shown in Fig. 1(a). A closer look at the primaryβ-LiZn4, as shown in the enlarged local region at the left corner of Fig. 2(b), reveals that there are dense secondary Zn needles within it. The hardness of the primaryβ-LiZn4 phase is measured to be 156 ± 6 HV, while that of the eutectic phase is 87 ± 4 HV.Fig. 2(c) shows SEM microstructure of the WR alloy viewed along TD. The microstructure is featured by alternative Zn andβ-LiZn4 bands. A local region in Fig. 2(c) is observed by a greater magnification as shown in Fig. 2(d). It can be seen that needle-like secondary Zn forms inβ-LiZn4, which has also been confirm in Zn-0.8Li alloy. Li has a negative standard electrode potential of -3.04 V, much lower than that of Zn (i.e., -0.76 V), so thatβ-LiZn4 is more vulnerable to the attack of the etching solution. As can be seen in Fig. 2(b–d), no matterβ-LiZn4 is in the primaryβ-LiZn4 or in the eutectic, it is always corroded more quickly than its surrounding Zn, resulting in a recessed topography and a darker color.As shown in Figure 2(d), it can be seen that acicular secondary Zn is formed in β-LiZn4, which is also confirmed in Zn-0.8Li alloy. Li has a negative standard electrode potential of -3.04 V, which is much lower than Zn (ie -0.76 V), so β-LiZn4 is more susceptible to corrosion by etching solutions. It can be seen from Fig. 2(b-d) that no matter whether β-LiZn4 is in the primary β-LiZn4 or in the eutectic, it will always corrode faster than the surrounding Zn, resulting in a concave morphology and a darker color.