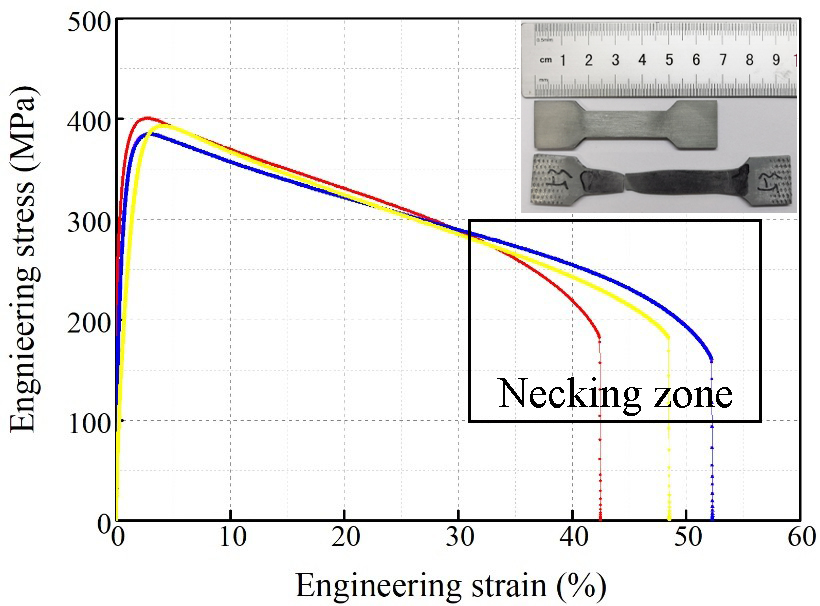

锌锂合金(WR)的三个平行拉伸试样的工程应力-应变曲线如图1(c)所示,在颈缩前非常相似(图1(d))。 平均颈缩区经测量为 17.3 %±5.1 %。 因此,均匀伸长率区域仍为 29.4%±1.9%,远好于许多可生物降解的锌合金。应该注意的是,颈缩不会在应变软化开始时开始,这可能是由于室温应力诱导 Zn 晶粒的再结晶,这是 Zn 合金的独特特征。此外,从图 1(c) 中 WR 合金的应变-应力曲线计算的韧性为 (1.56±0.11)×104MJ/m3,几乎是铸态合金的 20 倍,表明韧性断裂 WR合金。测量的平均颈缩区为17.3%±5.1%。因此,均匀延伸区域保持在29.4 %至1.9 %,比许多可生物降解的锌合金好得多。应该注意的是,颈缩不会在应变软化开始时开始,这可能是由于室温应力诱导的锌晶粒再结晶,这是锌合金的独特特征。

The engineering stress-strain curves of three parallel tensile specimens of the Zn-Li alloy (WR) are shown in Fig. 1(c), which are very similar before necking (Fig. 1(d)). The average necking zone is measured to be 17.3 %±5.1 %. So the uniform elongation region remains to be 29.4 %±1.9 %, much better than many biodegrade-able Zn alloys. It should be noted that the necking does not begin at the start of strain softening due probably to room temperature stress-induced recrystallization of Zn grains, which is a unique characteristic of Zn alloys. Additionally, the toughness calculated from strain-stress curves of WR alloy in Fig. 1(c) Is (1.56 ± 0.11)×104MJ/m3, which is almost 20 times higher than that of the as-cast alloy, indicating the ductile fracture of WR alloy.The average necked area measured was 17.3%±5.1%. Therefore, the uniform extension area is maintained at 29.4% to 1.9%, which is much better than many biodegradable zinc alloys. It should be noted that necking does not start at the beginning of strain softening, which may be due to the recrystallization of zinc grains induced by room temperature stress, which is a unique feature of zinc alloys.