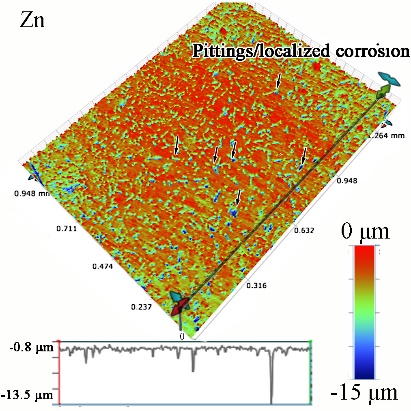

图8显示了浸没锌和锌合金腐蚀产物清洗后的WLIM形貌图。WLIM图中的颜色显示了表面的波动。在锌和ZnLi合金表面观察到坑和蓝色局部腐蚀。纯锌的最大坑深从13.5μm增至锌-0.5Li合金的16.8μm,然后锌-0.8Li合金降至9.2μm,Zn-1.4Li合金再次增至14.9μm。锌-0.2Li的严重点蚀/局部腐蚀(图8c)和锌-0.5Li(图8d)是由于锌-0.2Li合金晶界上分离二次β相和锌-0.5Li合金锌+β共晶体中分离二次β枝晶的电流腐蚀。锌-0.8Li合金的点蚀和局部腐蚀主要发生在呈绿色的初级枝晶β相中(图8e),它显示出比红色的锌+β共晶更严重的腐蚀。在初级β阶段,腐蚀也是不均匀的。在β/Zn层状结构中,β基质优先腐蚀为锌沉淀(图8g)。图8h为根据WLIM形貌分析,材料腐蚀表面腐蚀坑深度值中的最大值。锌、Zn-0.2Li合金、Zn-0.5Li合金的腐蚀坑深度比其他ZnLi合金要深得多,表明前者的点蚀更严重。

Fig. 8 shows the WLIM topographies of immersed Zn and ZnLi alloys after corrosion products cleaning. The colors in the WLIM maps show surface undulation. Pits and localized corrosion in blue color are observed on the surfaces of Zn and the ZneLi alloys. The maximum pit depth increases from 13.5 μm for pure Zn to 16.8 μm for Zn-0.5Li alloy, and then decrease to 9.2 μm for Zn-0.8Li alloy and again increase to 14.9 μm for Zn-1.4Li alloy. The severe pitting/localized corrosion of Zn-0.2Li (Fig. 8c) and Zn-0.5Li (Fig. 8d) is due to galvanic corrosion resulted from segregation of secondary β phase on grain boundaries for Zn-0.2Li alloy and isolated primary β dendrites in Zn + β eutectics for Zn-0.5Li alloy. Pitting and localized corrosion in Zn-0.8Li alloy mainly occur in primary dendritic β phase colored in green (Fig. 8e), which demonstrates a more severe corrosion than the Zn + β eutectics colored in red. In the primary β phase, corrosion is also non-uniform. In the β/Zn lamellar structure, β matrix is corroded preferentially to Zn precipitates (Fig. 8g).Fig. 8h shows the max. depth of corrosion pits of corroded surface on the materials according to an analysis of the WLIM topographies. The max. depths of the corrosion pits of Zn, Zn-0.2Li alloy, Zn-0.5Li alloy are much deeper than those of the other ZnLi alloys, revealing a more serious pitting corrosion in the former ones.