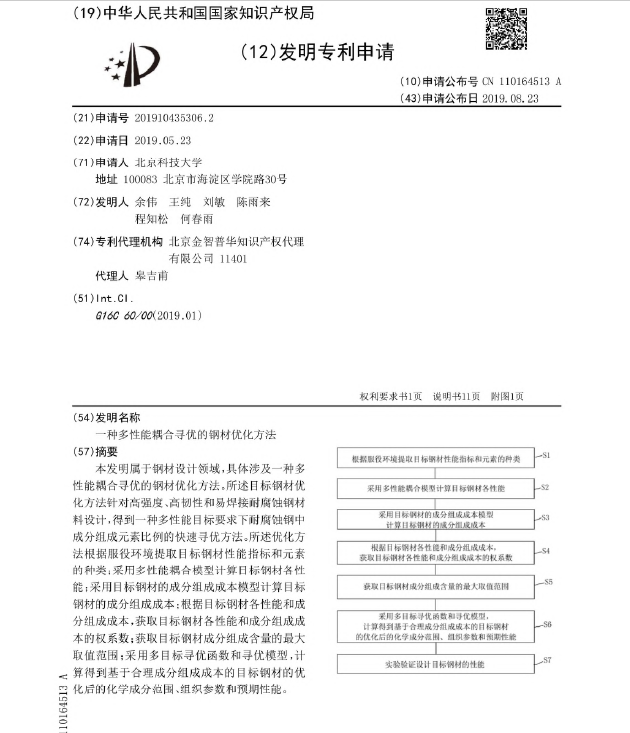

本发明属于钢材设计领域,具体涉及一种多性能耦合寻优的钢材优化方法。所述目标钢材优化方法针对高强度、高韧性和易焊接耐腐蚀钢材料设计,得到一种多性能目标要求下耐腐蚀钢中成分组成元素比例的快速寻优方法。所述优化方法根据服役环境提取目标钢材性能指标和元素的种类;采用多性能耦合模型计算目标钢材各性能;采用目标钢材的成分组成成本模型计算目标钢材的成分组成成本;根据目标钢材各性能和成分组成成本,获取目标钢材各性能和成分组成成本的权系数;获取目标钢材成分组成含量的最大取值范围;采用多目标寻优函数和寻优模型,计算得到基于合理成分组成成本的目标钢材的优化后的化学成分范围、组织参数和预期性能。

The invention belongs to the field of steel design, which specifically involves a steel optimization method of multi-performance coupling optimization. The target steel optimization method is designed for high strength, high toughness and easy welding corrosion resistant steel materials, and a fast optimization method for the proportion of constituent elements in corrosion resistant steel under multi-performance target requirements is obtained. The optimization method extracts the performance indexes and element types of the target steel according to the service environment ; the multi-performance coupling model is used to calculate the performance of the target steel ; the component cost model of target steel is used to calculate the component cost of target steel ; according to the performance and composition cost of the target steel, the weight coefficient of the performance and composition cost of the target steel is obtained. obtaining the maximum value range of the composition content of the target steel ; the optimized chemical composition range, microstructure parameters and expected performance of target steel based on reasonable composition cost are calculated by using multi-objective optimization function and optimization model.