双金属复合板应用时必然会涉及到材料的焊接,该材料焊接时,一般采用先焊接基层,然后焊接过渡层,最后焊接复层的原则。然而,由于焊接操作受空间、流程或者板厚的限制时,复合钢板的使用还会涉及从材料单侧进行焊接,即需采用单面焊接工艺。薄规格复合板单面焊接时,需要要求焊工掌握单面焊双面成形技术来保证焊道根部性能,且需要合理选择焊材,保证复合板接头复层侧的焊道表面的耐蚀性不低于复层,难度较大。

因此,发明一种操作难度低、焊材选择方案简单、焊后接头耐蚀性好的方法,成为薄规格复合板单面焊接的急需要求。

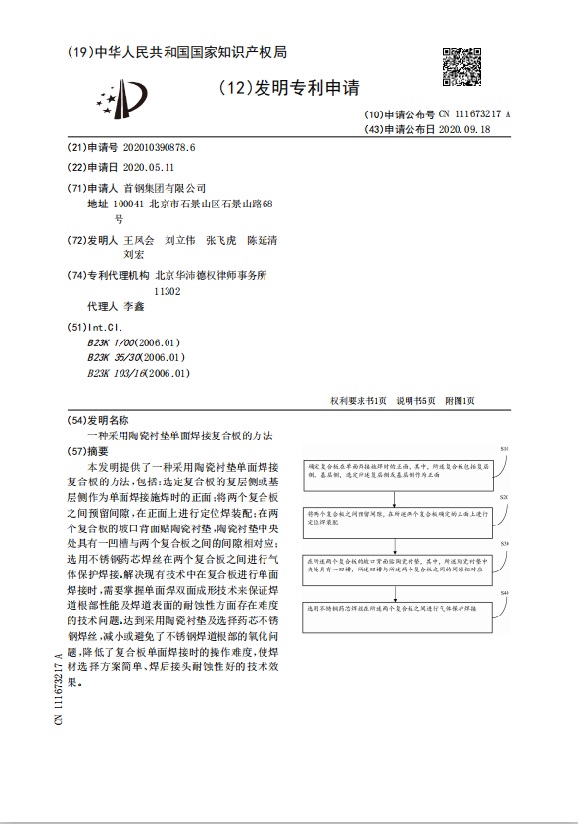

针对现有技术存在的问题,本发明提供了一种采用陶瓷衬垫单面焊接薄规格复合板的方法,采用该焊接方法复合板不需要开坡口,采用同一种焊材仅焊接一道即可完成复合板的焊接且实现焊道的单面焊接双面成形,对焊接操作人员的水平要求较低。

The application of the bimetal composite board will inevitably involve the welding of materials. When the material is welded, the principle of welding the base layer first, then welding the transition layer, and finally welding the cladding layer. However, when the welding operation is limited by space, process or plate thickness, the use of clad steel plates also involves welding from one side of the material, that is, a single-sided welding process is required. For single-sided welding of thin-gauge composite plates, the welder is required to master the single-sided welding and double-sided forming technology to ensure the performance of the weld bead root, and the welding consumables need to be selected reasonably to ensure that the corrosion resistance of the weld bead surface on the clad side of the composite plate joint is not Lower than multi-layer, more difficult.

Therefore, inventing a method with low operation difficulty, simple welding material selection plan, and good corrosion resistance of the joint after welding has become an urgent requirement for single-sided welding of thin-gauge composite panels.

In view of the problems in the prior art, the present invention provides a method for welding thin-gauge composite plates on one side with ceramic backing. The composite plate does not need to be grooved by this welding method, and only one welding material is required for welding with the same welding material. Complete the welding of the composite plate and realize the single-sided welding and double-sided forming of the weld bead, which requires lower levels of welding operators.