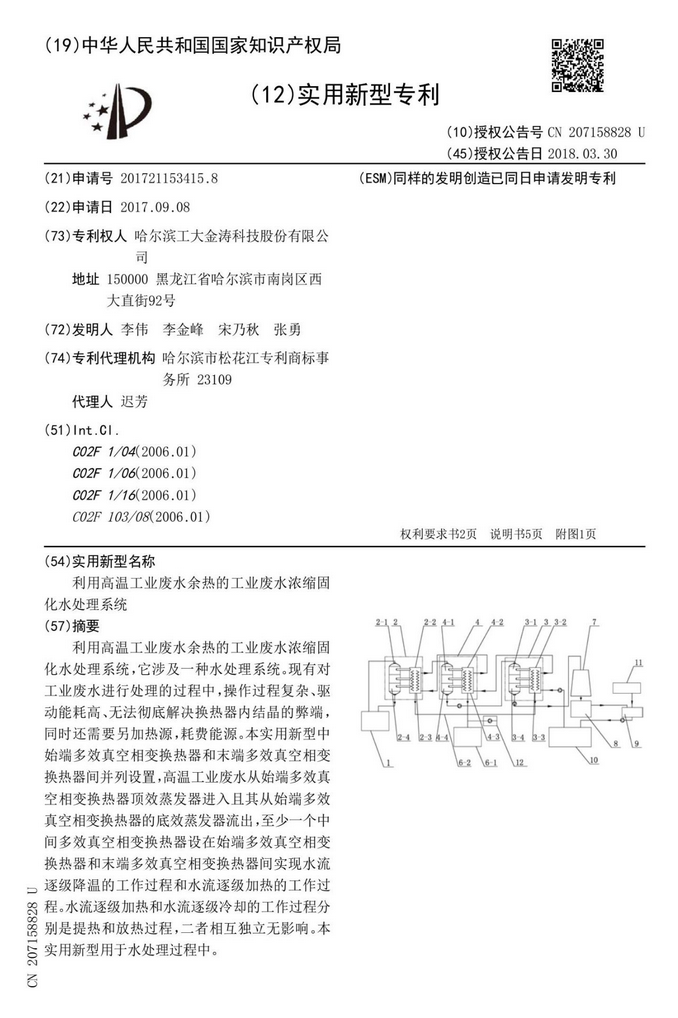

利用高温工业废水余热的工业废水浓缩固化水处理系统,它涉及一种水处理系统。现有对工业废水进行处理的过程中,操作过程复杂、驱动能耗高、无法彻底解决换热器内结晶的弊端,同时还需要另加热源,耗费能源。本实用新型中始端多效真空相变换热器和末端多效真空相变换热器间并列设置,高温工业废水从始端多效真空相变换热器顶效蒸发器进入且其从始端多效真空相变换热器的底效蒸发器流出,至少一个中间多效真空相变换热器设在始端多效真空相变换热器和末端多效真空相变换热器间实现水流逐级降温的工作过程和水流逐级加热的工作过程。水流逐级加热和水流逐级冷却的工作过程分别是提热和放热过程,二者相互独立无影响。本实用新型用于水处理过程中。

The utility model relates to a concentrated and solidified water treatment system for industrial wastewater using the waste heat of high-temperature industrial wastewater, which relates to a water treatment system. In the existing process of industrial wastewater treatment, the operation process is complex, the driving energy consumption is high, and the disadvantages of crystallization in the heat exchanger cannot be completely solved. At the same time, another heating source is needed, which consumes energy. Vacuum phase change heat exchanger in the utility model between multiple effect and the end of the multi-effect joint setting between vacuum phase change heat exchanger, high temperature industrial wastewater from the head top vacuum phase change heat exchanger multi-effect evaporator move into effect and its from the beginning, the bottom of a vacuum phase change heat exchanger effect evaporator, vacuum phase change heat exchanger in at least one intermediate multi-effect signalling multi-effect vacuum phase change heat exchanger and multi-effect vacuum phase transition at the end The working process of water flow cooling and water flow heating step by step is realized between the heat exchanger. The step-by-step heating and step-by-step cooling processes of water flow are heat raising and heat release processes respectively, and they have no influence on each other. The utility model is used in a water treatment process.