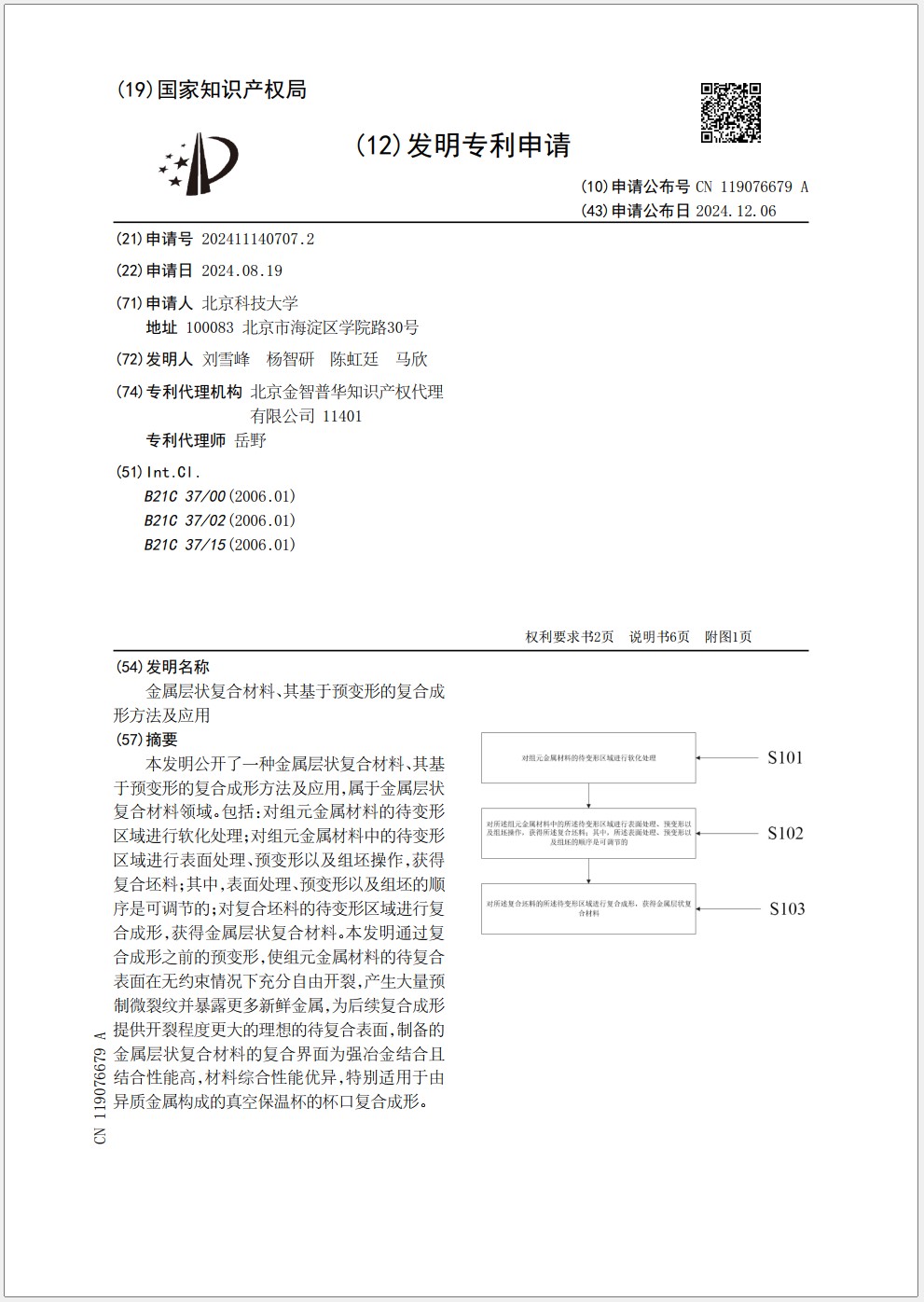

本发明公开了一种金属层状复合材料、其基于预变形的复合成形方法及应用, 属于金属层状复合材料领域。包括: 对组元金属材料的待变形区域进行软化处理; 对组元金属材料中的待变形区域进行表面处理、预变形以及组坯操作, 获得复合坯料; 其中, 表面处理、预变形以及组坯的顺序是可调节的; 对复合坯料的待变形区域进行复合成形, 获得金属层状复合材料。本发明通过复合成形之前的预变形, 使组元金属材料的待复合表面在无约束情况下充分自由开裂, 产生大量预制微裂纹并暴露更多新鲜金属, 为后续复合成形提供开裂程度更大的理想的待复合表面, 制备的金属层状复合材料的复合界面为强冶金结合且结合性能高, 材料综合性能优异, 特别适用于由异质金属构成的真空保温杯的杯口复合成形。

The present invention discloses a metal laminated composite material, a composite molding method based on predeformation thereof and an application thereof, and belongs to the field of metal laminated composite materials. It comprises: softening a region to be deformed of a component metal material; performing a surface treatment, a pre-deformation and a billet forming operation on the region to be deformed of the component metal material to obtain a composite blank; wherein the order of the surface treatment, the pre-deformation and the billet forming is adjustable; and composite molding the region to be deformed of the composite blank to obtain the metal laminated composite material. The present invention, through the pre-deformation before composite forming, makes the surface to be composited of the constituent metal material crack freely without constraints, produces a large number of prefabricated microcracks and exposes more fresh metal, and provides an ideal surface to be composited with a greater degree of cracking for the subsequent composite forming, and the composite interface of the metal layered composite material prepared is a strong metallurgical bond with high bonding properties, and the overall performance of the material is excellent, which is particularly suitable for the manufacture of the metal layered composite material made of the material. It is especially suitable for composite molding of the mouth of vacuum insulation cups composed of heterogeneous metals.